TM

Construiţi pentru viitorul automatizărilor

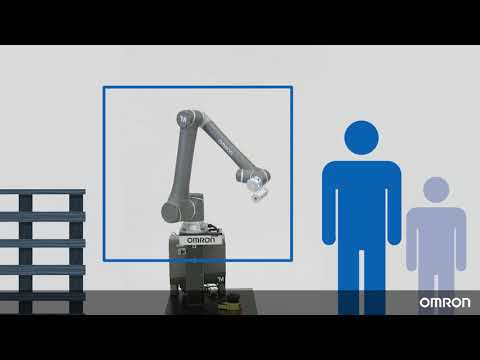

- Conceput pentru a promova un loc de muncă sigur şi armonios între oameni şi maşini.

- 31 de funcţii de securitate, toate certificate ISO 13849-1, Cat.3, PLd, certificate.

- Conformitate completă cu ISO 10218-1.

- Mediu de programare grafică uşor de utilizat pentru pornire şi funcţionare rapide.

- Controlul încorporat al robotului bazat pe cameră de inspecție video permite efectuarea operaţiunilor de asistare vizuală, de inspecţie şi de măsurare.

- Camera opţională şi eticheta Landmark permit o schimbare cu adevărat flexibilă şi rapidă.

- Capacitatea de integrare cu roboţi mobili permite aplicaţii complet autonome de supraveghere a maşinilor şi de manipulare logistică.

- Modele Fieldbus, inclusiv EtherNet/IP şi Profinet.

-

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!

02:23

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!Robotul colaborativ

Omron TM12 cobot automates booklet feeding for Kraus Maschinenbau

Cobots streamline processes in medtech and packaging industry

Caracteristici

Configurare mai rapidă prin inspecţie vizuală încorporată

-

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!

02:23

Pornire şi comutare rapidă

Securitatea muncii în aplicaţiile colaborative

Cobot Safety Articol expert

Cobot and flexible production - Future-proofing SMEs?

Many countries in Europe, such as the UK and Germany are likely to experience serious labour shortages over the coming decade, especially in relation to technical specialists. At the same time, product lifecycles are becoming shorter. Despite this, small and medium-sized enterprises (SMEs) might be reluctant to invest in additional automation. However, collaborative robots (cobots) are easy to set up and offer a quick and cost-effective solution. They can increase the flexibility, quality and speed of production and enable companies to respond rapidly to changing market conditions. Omron’s TM series of cobots are a good example of this versatility.

Modele

TM5S

- Rază de acţiune (mm): 900

- Sarcină utilă maximă (kg): 5

- Viteză maximă (m/s): 1,4

TM7S

- Rază de acţiune (mm): 700

- Sarcină utilă maximă (kg): 7

- Viteză maximă (m/s): 1,1

TM12S

- Rază de acţiune (mm): 1300

- Sarcină utilă maximă (kg): 12

- Viteză maximă (m/s): 1,3

TM14S

- Rază de acţiune (mm): 1100

- Sarcină utilă maximă (kg): 14

- Viteză maximă (m/s): 1,1

TM 5 – 700

- Rază de acţiune (mm): 700

- Sarcină utilă maximă (kg): 6

- Viteză maximă (m/s): 1,1

TM 5 – 900

- Rază de acţiune (mm): 900

- Sarcină utilă maximă (kg): 4

- Viteză maximă (m/s): 1,4

TM12

- Rază de acţiune (mm): 1300

- Sarcină utilă maximă (kg): 12

- Viteză maximă (m/s): 1,3

TM14

- Rază de acţiune (mm): 1100

- Sarcină utilă maximă (kg): 14

- Viteză maximă (m/s): 1,1

TM16

- Rază de acţiune (mm): 900

- Sarcină utilă maximă (kg): 16

- Viteză maximă (m/s): 1,1

TM20

- Rază de acţiune (mm): 1300

- Sarcină utilă maximă (kg): 20

- Viteză maximă (m/s): 1,3

Specificaţii şi informaţii pentru comenzi

| Produs | Hardware version | Payload | Reach | PROFINET communication | EtherNet/IP communication | Vision | Power supply type | SEMI S2 certified | Food grade grease | SIL according to IEC 61508 | Performance level according to EN ISO 13849-1 | Cable length | Descriere | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-700, 12 m cable, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-700, 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-900, 12 m cable, HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-900, 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-700 (model without camera), 12 m cable, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-700 (model without camera), 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | No | No | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-900 (model without camera), HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | No | No | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-900 (model without camera), 12 m cable, HW3.2 |

|

Suntem aici pentru a vă ajuta

Aveţi o întrebare? Specialiştii noştri sunt pregătiţi să vă ajute la fiecare pas al parcursului.

Contactați-mă TM

Vă mulțumim pentru solicitarea trimisă. Vom reveni cu un răspuns cât mai curând posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadOfertă pentru TM

Prin completarea acestui formular puteţi face o cerere de ofertă. Vã rugãm completaţi toate câmpurile marcate cu *. Datele dumneavoastrã personale vor fi tratate cu confidențialitate.

Vă mulțumim pentru cererea de ofertă trimisă. Vă vom oferi informațiile cerute în cel mai scurt timp posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadCazuri clienţi

Cobots give gear manufacturer a competitive production edge

Danish gear manufacturer, Fischer Gears, has boosted the competitiveness of its production process - especially on larger series – by installing two OMRON TM robots. The collaborative robots (cobots) free experienced employees to focus on more value-adding tasks.

Aplicaţia inovatoare cu cobot îmbunătăţeşte securitatea muncii în compania Leica Geosystems

Robotul colaborativ automatizează manevrarea tăvilor şi îmbunătăţeşte securitatea muncii şi ergonomia într-o zonă de lucru periculoasă.

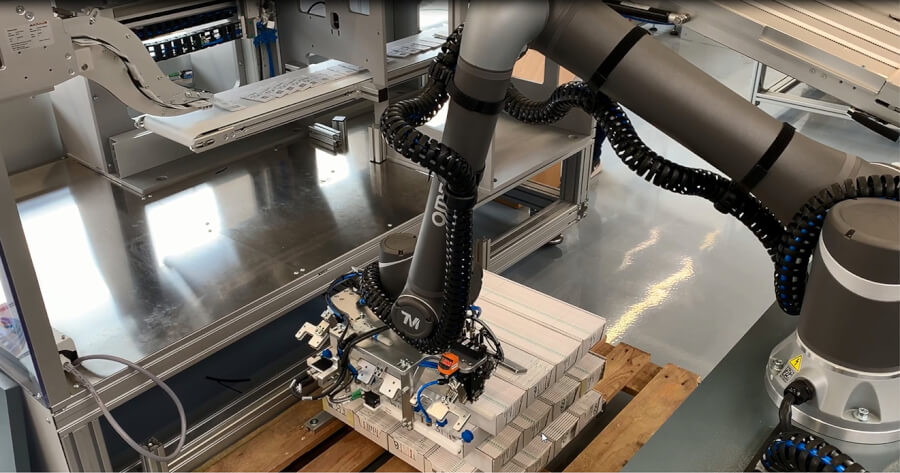

Roboţii colaborativi optimizează productivitatea la CLECA

Procesul de paletizare este automatizat cu ajutorul coboţilor OMRON TM12

Soluţia de paletizare de la Reitec satisface nevoile clienţilor FMCG

OMRON şi Reitec îşi unesc forţele pentru a crea o nouă soluţie de paletizare cu coboţi RC-1

Cobot paletizator agil de la Reeco Automation

Amprentă redusă cu 60% şi costuri mai mici cu până la 50% comparativ cu roboţii paletizatori convenţionali

Trasabilitate 4.0 cu ajutorul soluţiei optimizate de etichetare cu coboţi

În cadrul unei soluţii create de Bluengineering pentru Gruppo Romani din Italia, robotul colaborativ efectuează operaţii inteligente de etichetare pe diferite formate de produse, reducând cu până la 70 % timpul de inactivitate cauzat de schimbările de format.

Cisel asigură trasabilitatea, siguranţa şi calitatea prin testarea plăcilor de circuite imprimate cu ajutorul unui cobot

Cisel este o companie italiană specializată în proiectarea şi producţia de plăci de circuite imprimate flexibile (PCB-uri) pentru industria auto, construcţii civile şi industria prelucrătoare. Compania a ales de curând robotul colaborativ (cobotul) OMRON TM5 pentru a automatiza testarea electrică a plăcilor utilizate în sistemul de direcţie electrică a unui producător auto de top.

Un cobot asigură asamblarea precisă a magneţilor pentru buşoanele de golire de la LITMAT

Roboţii colaborativi (coboţii) se folosesc la scară tot mai mare, în diverse sectoare industriale şi în cadrul unei game vaste de aplicaţii. Aceştia pot influenţa semnificativ eficienţa şi productivitatea ciclului de producţie. Una dintre companiile care beneficiază de asemenea avantaje este LITMAT SpA.

Unika ia o decizie de referinţă pentru a aduce nivelurile de calitate pe noi culmi

Coboţii OMRON TM cu sistem integrat de inspecţie cu cameră video elimină eroarea umană şi măresc eficienţa producţiei.

Aplicaţii

Soluţii

Soluţie Omron de manipulator mobil

Soluţia unică de concept hibrid de cobot şi robot mobil de la OMRON

Soluţie de paletizare cu coboţi

Software pentru „FB” PLC Sysmac de la OMRON

Tutoriale video

-

Omron Collaborative can draw!

Omron Collaborative Robot can be used for a variety of purposes and numerous applications especially machine tending, loading and unloading, assembling, gluing, testing, and soldering! On this video you can see just one of them, drawing Omron’s logo with a pen on the blackboard! Just amazing Omron Collaborative Robots can do.

00:31

Omron Collaborative can draw!

Omron Collaborative Robot can be used for a variety of purposes and numerous applications especially machine tending, loading and unloading, assembling, gluing, testing, and soldering! On this video you can see just one of them, drawing Omron’s logo with a pen on the blackboard! Just amazing Omron Collaborative Robots can do.

-

Omron Collaborative Robots Tutorial 1 - Unboxing and Initial Set Up

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show you how to unbox the Cobot and do the initial set up. There are several Cobot in the TM Series depending on your needs. Here we will be using the TM5 – 700 models to explain the common features.

06:34

Omron Collaborative Robots Tutorial 1 - Unboxing and Initial Set Up

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show you how to unbox the Cobot and do the initial set up. There are several Cobot in the TM Series depending on your needs. Here we will be using the TM5 – 700 models to explain the common features.

-

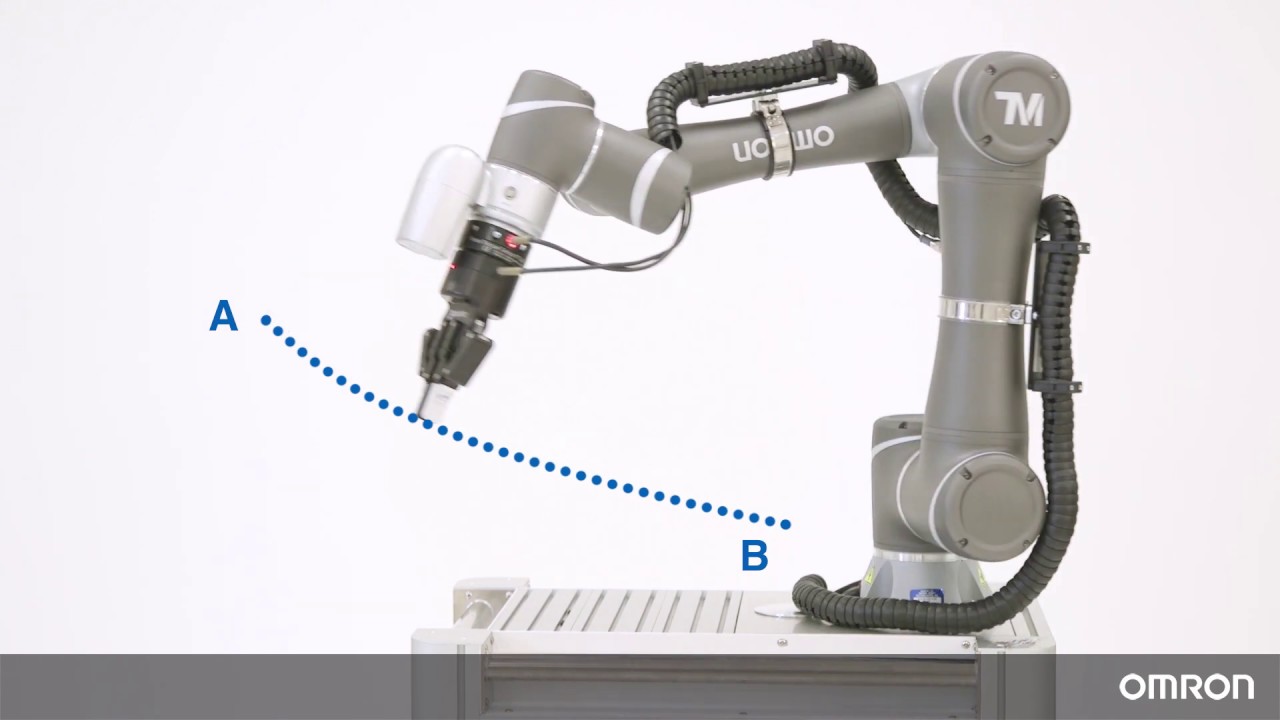

Omron Collaborative Robots Tutorial 2 – Programming the Basic Motions

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we would like to show you the basics of how to make the Cobot move.

06:40

Omron Collaborative Robots Tutorial 2 – Programming the Basic Motions

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we would like to show you the basics of how to make the Cobot move.

-

Omron Collaborative Robots Tutorial 3 – How to Program Using Flow Chart Software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, you can learn how to use the software, called “TMflow,” to program the Cobots. TMflow has an intuitive user interface that allows you to easily create a program using flowcharts.

05:23

Omron Collaborative Robots Tutorial 3 – How to Program Using Flow Chart Software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, you can learn how to use the software, called “TMflow,” to program the Cobots. TMflow has an intuitive user interface that allows you to easily create a program using flowcharts.

-

Omron Collaborative Robots Tutorial 4 – How to Attach a Gripper to the Cobot

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to use grippers with your Cobot.

04:37

Omron Collaborative Robots Tutorial 4 – How to Attach a Gripper to the Cobot

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to use grippers with your Cobot.

-

Omron Collaborative Robots Tutorial 5 – Vision Calibration and Vision Node

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to start using the built-in camera and the integrated vision system for your applications. One of the biggest advantages of this Cobot is that you can rapidly create an application in which you want the Cobot to see and recognize the object that it is working on. You do not need additional lens nor lights.

05:13

Omron Collaborative Robots Tutorial 5 – Vision Calibration and Vision Node

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to start using the built-in camera and the integrated vision system for your applications. One of the biggest advantages of this Cobot is that you can rapidly create an application in which you want the Cobot to see and recognize the object that it is working on. You do not need additional lens nor lights.

-

Omron Collaborative Robots Tutorial 6 – Pick and Place Using Vision

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we finished the vision calibration and explored some of the vision tasks. So now we are ready to start creating an application that utilizes the camera and the vision system. We will pick up a cylinder from this hole and place it here.

06:46

Omron Collaborative Robots Tutorial 6 – Pick and Place Using Vision

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we finished the vision calibration and explored some of the vision tasks. So now we are ready to start creating an application that utilizes the camera and the vision system. We will pick up a cylinder from this hole and place it here.

-

Omron Collaborative Robots Tutorial 7 – Updating TMFlow software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show how to update the TMFlow software. We constantly have software updates, so make sure you update Collaborative Robots software so that you can utilize the newest features.

04:49

Omron Collaborative Robots Tutorial 7 – Updating TMFlow software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show how to update the TMFlow software. We constantly have software updates, so make sure you update Collaborative Robots software so that you can utilize the newest features.

-

Omron Collaborative Robots Tutorial 8 – Communication via ModBus

Meet the Omron Collaborative Robot Series to assist your automation needs. The Omron Collaborative Robots is capable of different types of communications. On this video we will focus on using ModBus TCP communication in TMFlow software.

07:15

Omron Collaborative Robots Tutorial 8 – Communication via ModBus

Meet the Omron Collaborative Robot Series to assist your automation needs. The Omron Collaborative Robots is capable of different types of communications. On this video we will focus on using ModBus TCP communication in TMFlow software.

-

Omron Collaborative Robots Tutorial 9 – Advanced Motion Methods

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will discuss the different types of advanced motions that Omron’s Collaborative Robots can achieve. We will focus on some of the different types of motions that our Cobots can use to fit in your applications.

04:32

Omron Collaborative Robots Tutorial 9 – Advanced Motion Methods

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will discuss the different types of advanced motions that Omron’s Collaborative Robots can achieve. We will focus on some of the different types of motions that our Cobots can use to fit in your applications.

-

Collaborative Robot Safety Tutorial - Video 1

Watch this safety video to learn about Omron's Collaborative Robot safety features. Safety Standards & Safety Functions, Emergency Stop & Protective Stop and Safety Output Functions will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

05:50

Collaborative Robot Safety Tutorial - Video 1

Watch this safety video to learn about Omron's Collaborative Robot safety features. Safety Standards & Safety Functions, Emergency Stop & Protective Stop and Safety Output Functions will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

-

Collaborative Robot Safety Tutorial - Video 2

Watch this second part safety video to learn even more about Omron's Collaborative Robot safety features. Intuitive Safety Parameter Setting, Cartesian Safety Limit and Omron Risk Assessment Service will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

06:55

Collaborative Robot Safety Tutorial - Video 2

Watch this second part safety video to learn even more about Omron's Collaborative Robot safety features. Intuitive Safety Parameter Setting, Cartesian Safety Limit and Omron Risk Assessment Service will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.Descărcări

Servicii

Aveţi nevoie de asistenţă?

Suntem aici pentru a vă ajuta! Contactaţi-ne, iar specialiştii noştri vă vor ajuta să găsiţi cea mai bună soluţie pentru afacerea dvs.

Contactați-mă TM

Vă mulțumim pentru solicitarea trimisă. Vom reveni cu un răspuns cât mai curând posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadOfertă pentru TM

Prin completarea acestui formular puteţi face o cerere de ofertă. Vã rugãm completaţi toate câmpurile marcate cu *. Datele dumneavoastrã personale vor fi tratate cu confidențialitate.

Vă mulțumim pentru cererea de ofertă trimisă. Vă vom oferi informațiile cerute în cel mai scurt timp posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

Download