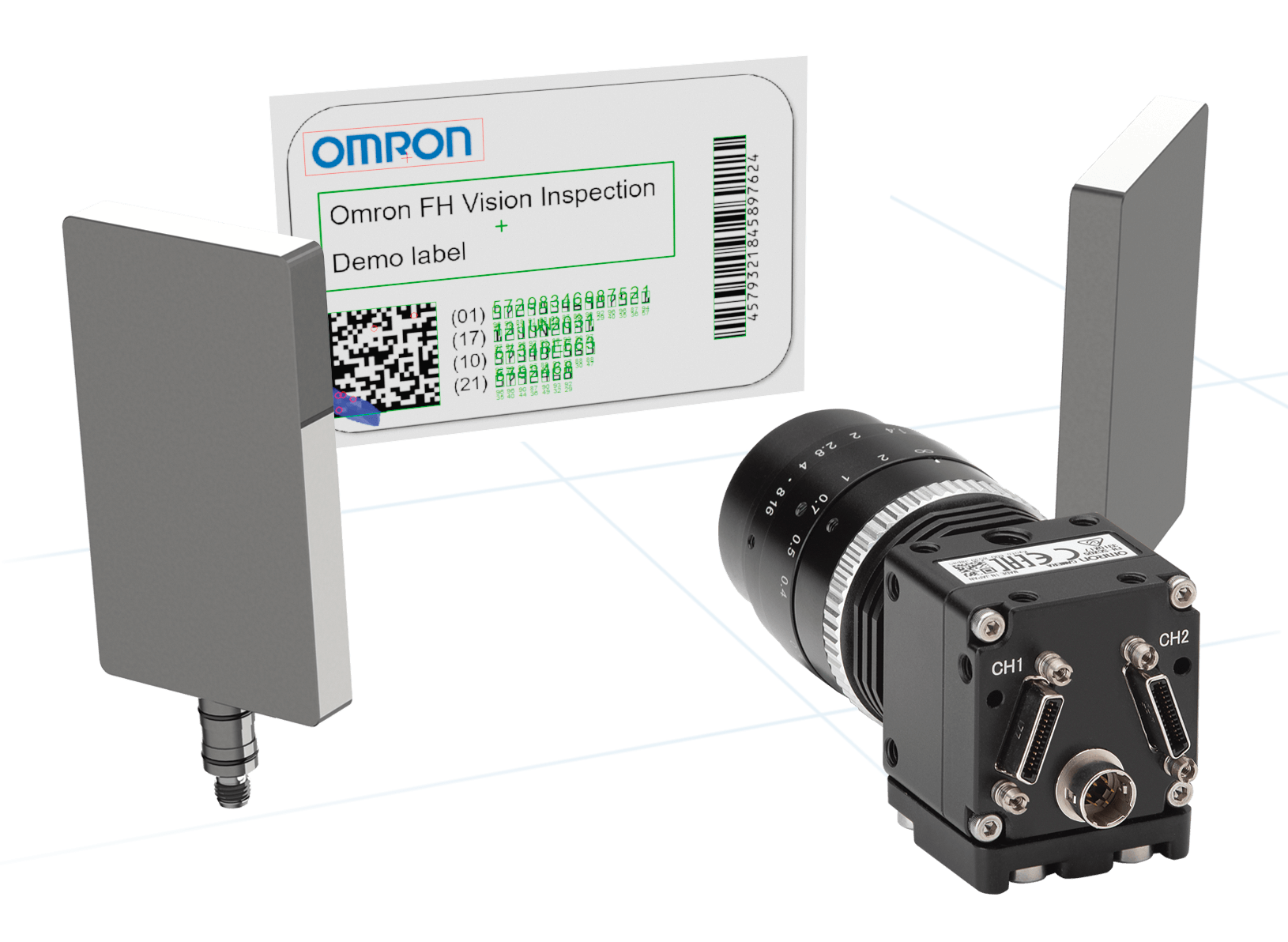

Sistem FH de inspecţie cu cameră video

Funcţionare mai rapidă a aparatului, camere pentru fiecare aplicaţie

- Imagistică de înaltă rezoluţie: Capturaţi detaliile fine şi defectele subtile cu o claritate excepţională.

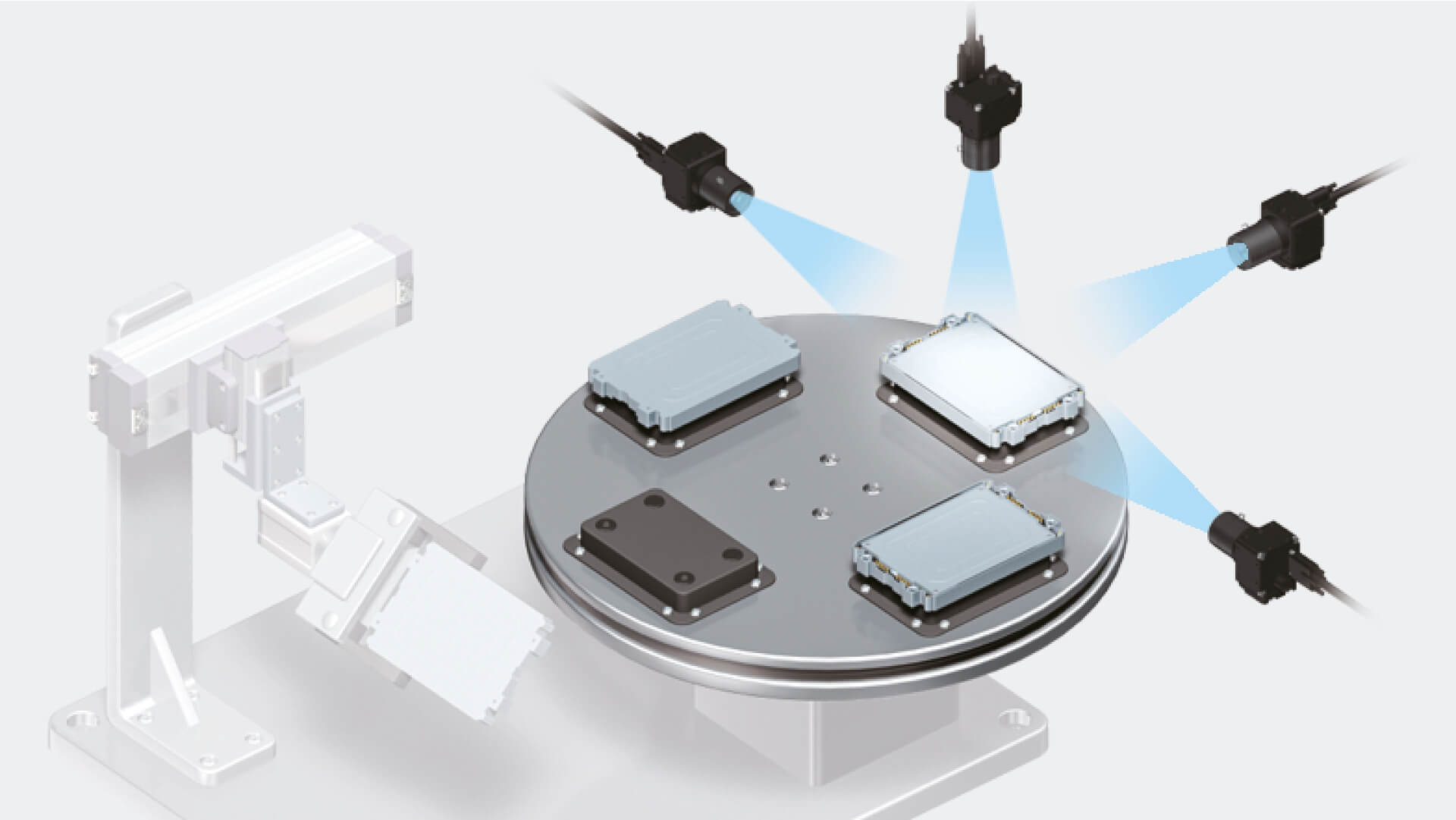

- Suport pentru mai multe camere: Integraţi fără probleme mai multe camere pentru o acoperire cuprinzătoare a inspecţiei.

- Instrumente de inspecţie personalizabile: Adaptaţi criteriile de inspecţie pentru a corespunde cerinţelor dvs. specifice, cu o gamă largă de instrumente integrate.

- Monitorizare şi control la distanţă: Monitorizaţi liniile de producţie şi gestionaţi inspecţiile de la distanţă, pentru eficienţă şi confort sporite.

- Capacităţi solide de integrare: Integraţi cu uşurinţă sistemul nostru de inspecţie cu cameră video FH cu utilajele şi cu sistemele de automatizare existente, pentru o funcţionare fără întreruperi.

- Suport pentru camere Linescan: Conectaţi până la 4 camere Omron Sentech GigE Linescan, opţiuni 2K, 4K şi 8K.

Aveţi nevoie de asistenţă?

Suntem aici pentru a vă ajuta! Contactaţi-ne, iar specialiştii noştri vă vor ajuta să găsiţi cea mai bună soluţie pentru afacerea dvs.

Contactați-mă Sistem FH de inspecţie cu cameră video

Vă mulțumim pentru solicitarea trimisă. Vom reveni cu un răspuns cât mai curând posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadOfertă pentru Sistem FH de inspecţie cu cameră video

Prin completarea acestui formular puteţi face o cerere de ofertă. Vã rugãm completaţi toate câmpurile marcate cu *. Datele dumneavoastrã personale vor fi tratate cu confidențialitate.

Vă mulțumim pentru cererea de ofertă trimisă. Vă vom oferi informațiile cerute în cel mai scurt timp posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadCaracteristici

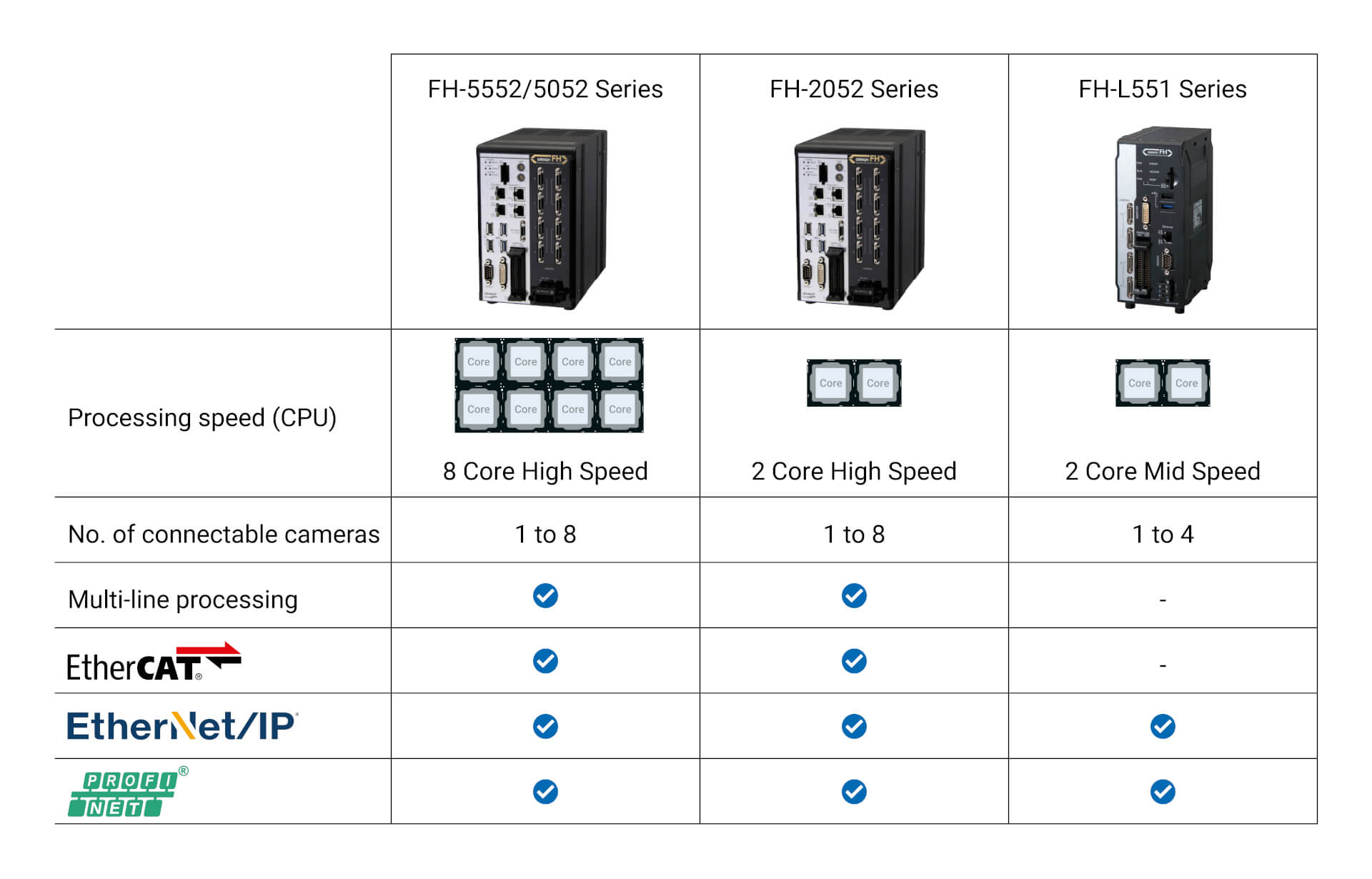

Controlere performante, pentru inspecţii şi măsurări rapide şi precise

Selectaţi cel mai bun controler, pentru a se potrivi cerinţelor dvs. Toate controlerele pot partaja aceleaşi setări, aducând flexibilitate în designul maşinii.

Gamă completă de camere de mare viteză/înaltă rezoluţie

Camerele FH proiectate pentru utilizare în toate tipurile de aplicaţii pentru măsurare, poziţionare/orientare, citire de coduri şi inspecţie de obiecte, această cameră compactă şi sistemul de controler este uşor integrat în aproape orice dispozitiv sau robot. Sistemul are capacitatea unică de a oferi rezultate mai rapide şi mai precise, aducându-vă costuri mai mici, eficienţă sporită şi nu doar atât.

Detectare extinsă cu camere SWIR şi polarizate

Omron şi-a avansat semnificativ capacităţile de detecție a imaginii, prin extinderea portofoliului de camere. Oferim acum două rezoluţii de cameră SWIR şi două camere cu rezoluţie polarizată. Aceste adăugiri îmbunătăţesc foarte mult intervalul de detecție şi versatilitatea gamei FH

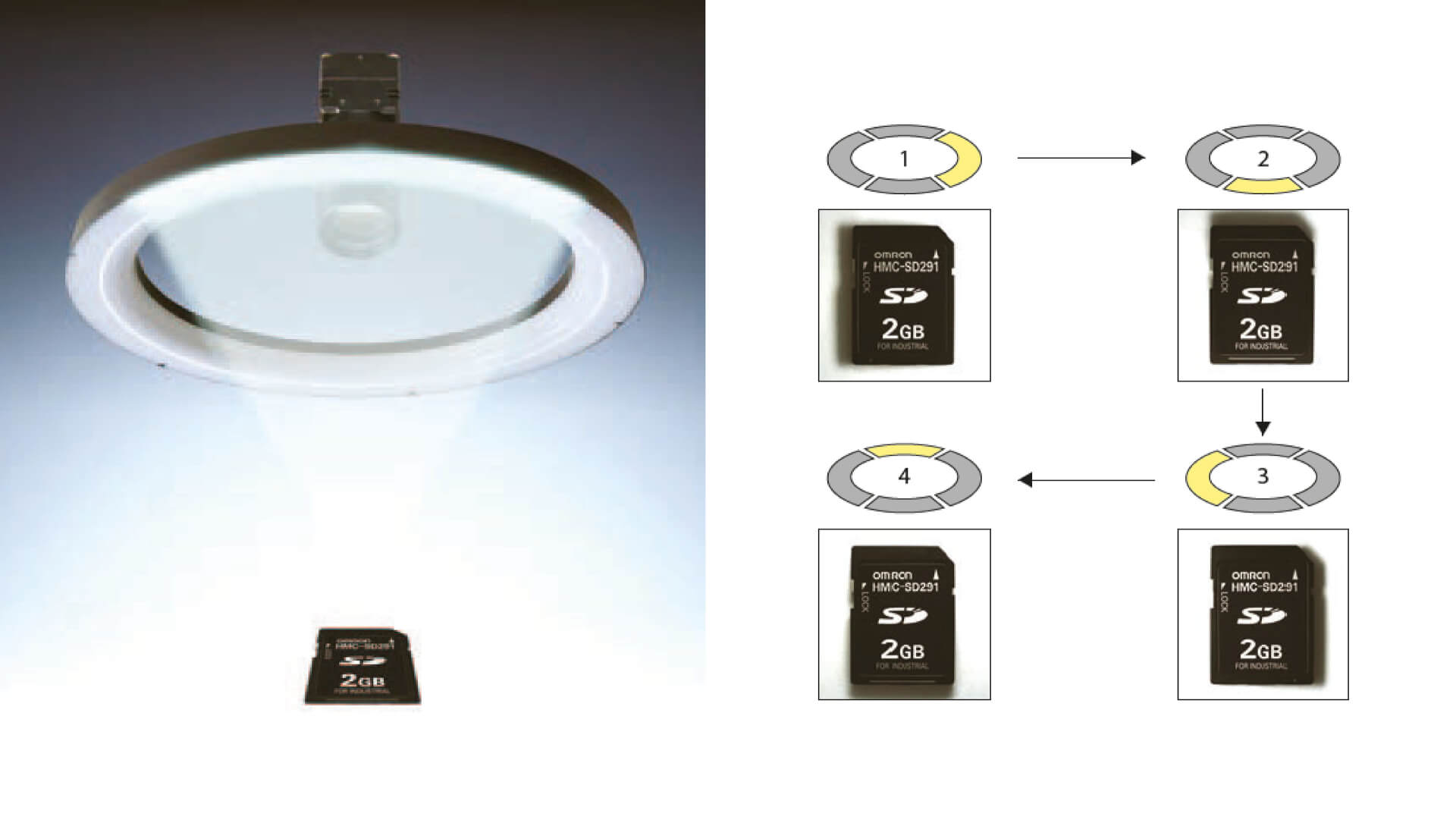

Imagistică fotometrică avansată

Lumina stereo fotometrică FH poate fi utilizată cu camere standard sau de înaltă rezoluţie de până la 20,4 Mpix. Pentru a detecta cu precizie ridicată urmele de lovituri şi deteriorarea suprafeţei. Patru lumini sunt aprinse la rândul lor, iar variaţiile de luminozitate sunt analizate. Caracterele imprimate cu mici variaţii de luminozitate, chiar şi în diferite direcţii de iluminare sunt extrase ca textură, iar o adâncitură cu variaţie semnificativă a luminozităţii este extrasă ca formă

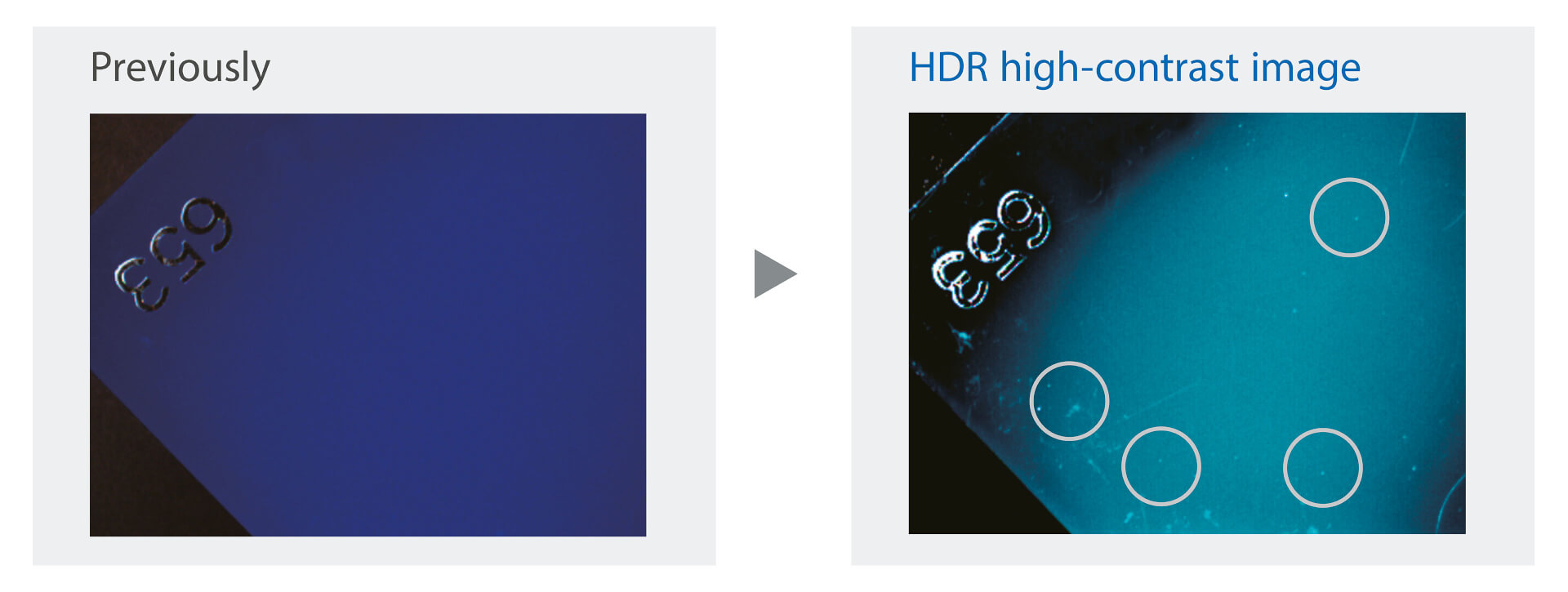

Imagistică HDR

HDR ajută la crearea de imagini optimizate în condiţii ambientale variabile. Odată ce specificaţi zona optimă pentru capturarea imaginii, seria FH reglează automat viteza obturatorului în timp ce capturează imagini şi le combină.

Instrumente complete de inspecţie cu cameră video bazate pe reguli

Instrumentele de inspecţie cu cameră video Omron FH bazate pe reguli sunt lider în automatizarea industrială modernă, oferind soluţii de ultimă oră pentru controlul calităţii, inspecţie şi optimizarea proceselor. Utilizând algoritmi avansaţi şi tehnologie de imagistică precisă, aceste instrumente execută sarcini complexe cu precizie şi cu fiabilitate excepţionale. Proiectate pentru a fi uşor de utilizat, instrumentele de inspecţie cu cameră video de la Omron asigură o integrare perfectă în sistemele existente şi necesită un timp minim de configurare.

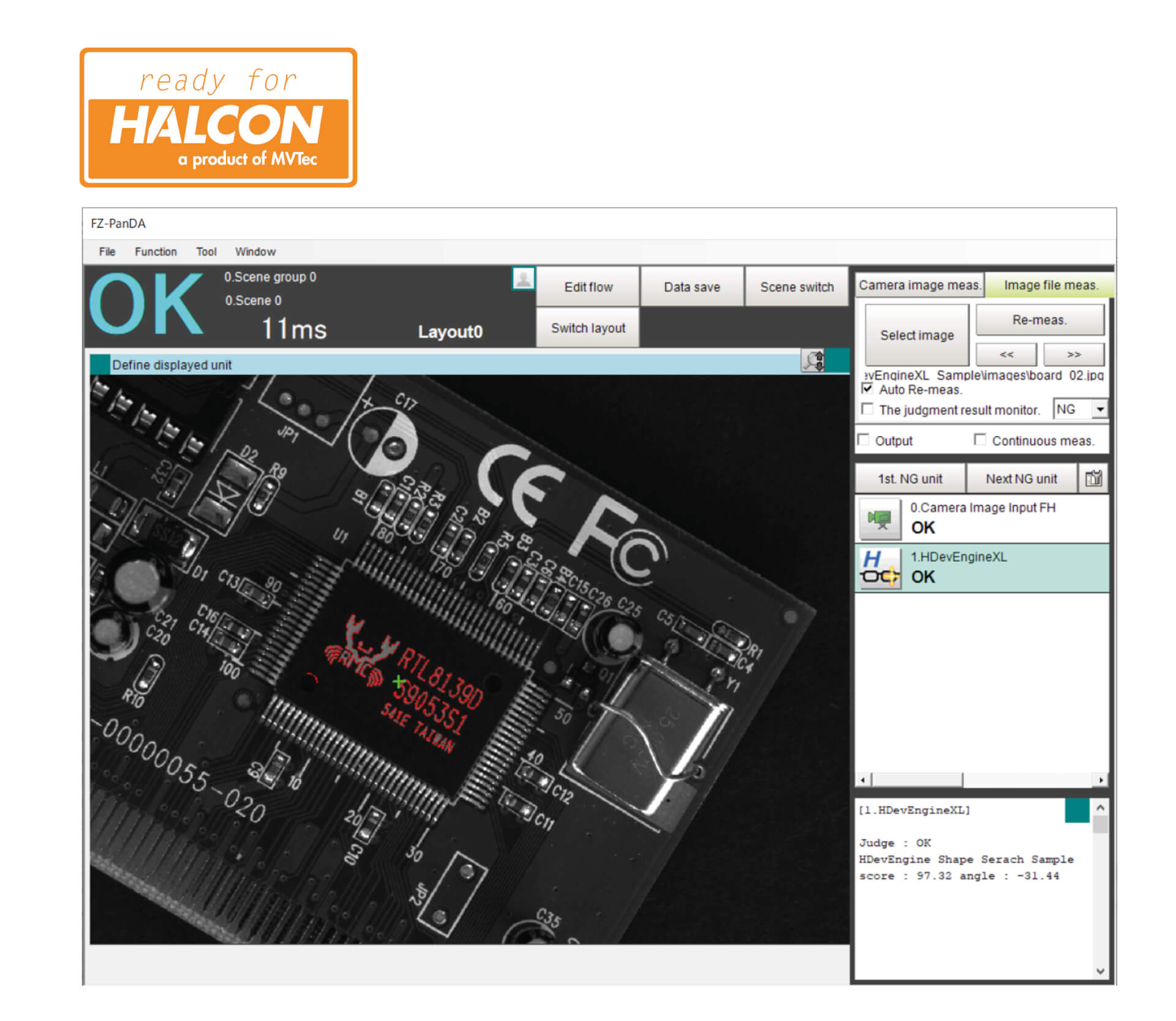

Deschidere FH

Pe lângă algoritmii de inspecţie cu cameră video patentaţi de Omron, controlerul de inspecţie cu cameră video FH este compatibil cu algoritmii de inspecţie cu cameră video dezvoltaţi care utilizează software-ul Halcon HDevelop de la MVTec. Această flexibilitate le permite producătorilor să selecteze cea mai bună abordare algoritmică pentru cerinţele specifice ale aplicaţiilor lor, asigurând performanţe şi eficienţă optime în soluţiile lor vizuale

AI Features

Inteligenţă artificială şi procesare bazată pe reguli

Hardware stabil şi fiabil:

Hardware-ul de inspecţie cu cameră video de la Omron este proiectat să reziste mediilor industriale exigente, oferind performanţe constante, chiar şi în condiţii dificile. Construcţia sa robustă asigură fiabilitatea pe termen lung, reducând timpii de inactivitate şi eforturile de întreţinere.

Integrarea fără probleme a instrumentelor de inspecţie pe bază de inteligenţă artificială:

Îmbunătăţiţi-vă sistemul tradiţional de inspecţie bazat pe reguli cu capabilităţi de inteligenţă artificială. Seria FH de la Omron vă permite să adăugaţi instrumente avansate de inspecţie bazate pe inteligenţă artificială la configuraţia dvs. existentă, combinând precizia inspecţiei bazate pe reguli cu adaptabilitatea analizei bazate pe inteligenţă artificială.

Model de licenţă perpetuă eficient din punct de vedere al costurilor:

Luaţi-vă adio de la problemele legate de bugetul anual şi de reînnoirea contractelor. Seria FH de la Omron oferă un model de licenţă perpetuă, oferindu-vă acces pe termen lung la tehnologia de inspecţie de ultimă oră, fără taxe recurente de abonament.

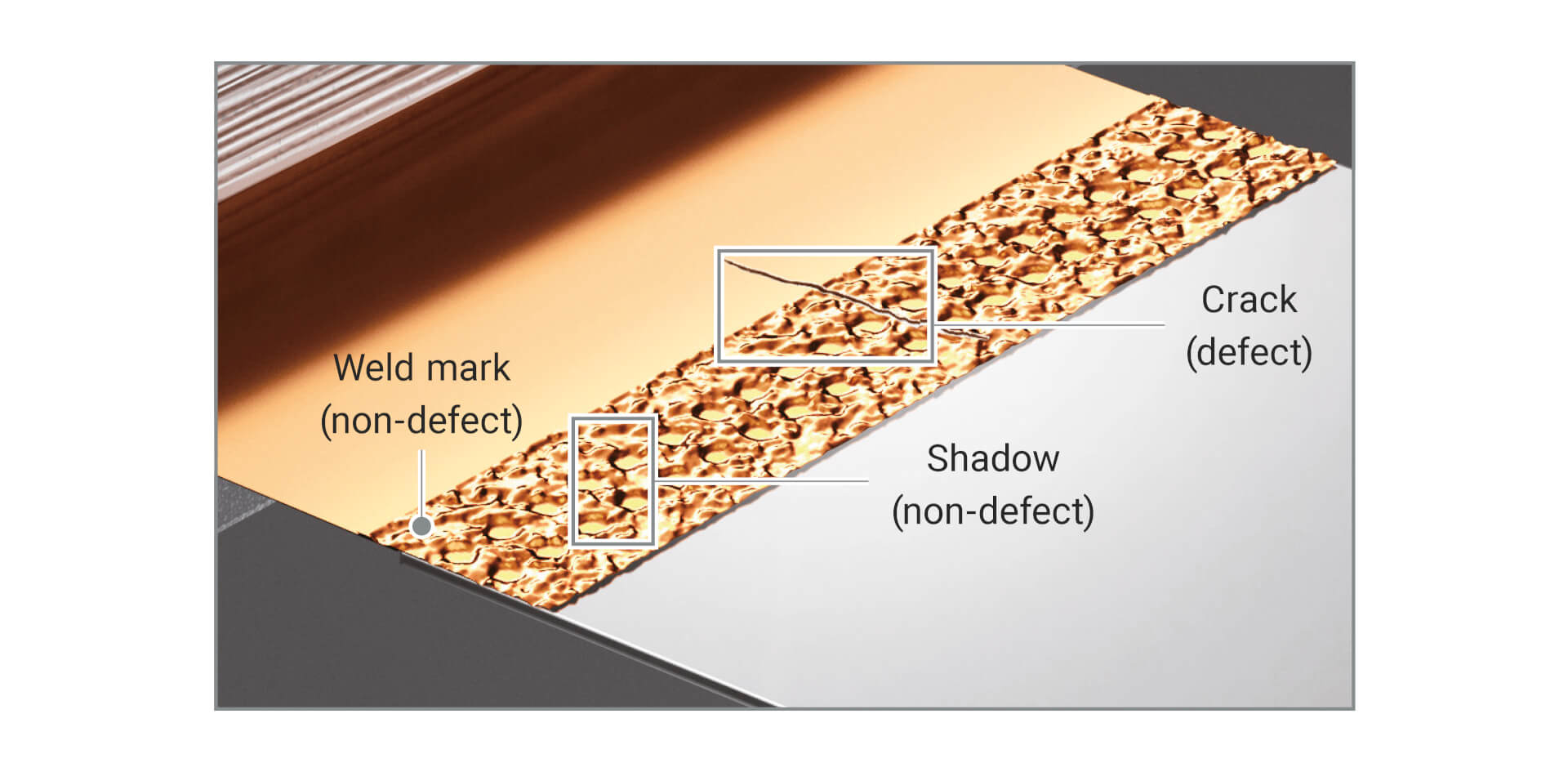

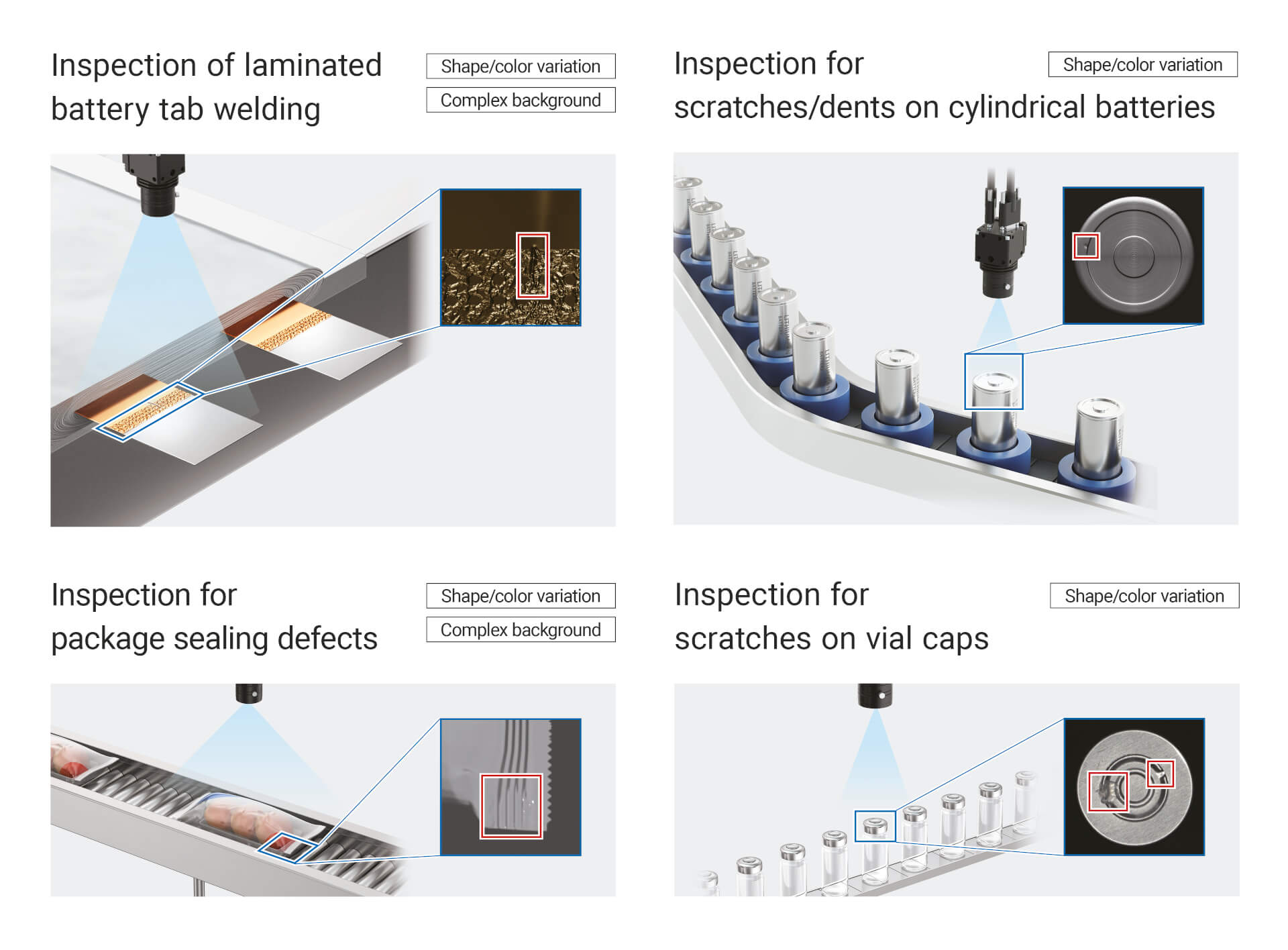

Inspectare defecte cu inteligenţă artificială

Algoritmul Omron de inspectare defecte cu inteligenţa artificială este o schimbare în ceea ce priveşte controlul calităţii. Acesta utilizează inteligenţa artificială avansată pentru a detecta defectele cu acurateţe, menţinând în acelaşi timp la un nivel minim falsurile pozitive. Acest sistem este conceput pentru a aborda provocări comune, cum ar fi variaţiile de formă, de culoare şi de luciu, precum şi fundalurile dificile, făcând inspecţia în timp real în fabrică mai precisă şi mai eficientă. Ceea ce îl diferenţiază cu adevărat este capacitatea sa de autoînvăţare şi configurarea uşoară în trei etape, făcând simplă şi fiabilă detectarea defectelor sofisticate. Indiferent dacă lucraţi în industria auto, electronică, alimentară sau farmaceutică, soluţiile inteligente Omron de inspecţie cu cameră video vă oferă precizia şi eficienţa de care aveţi nevoie.

Procesul de configurare în 3 etape

- Pregătirea imaginilor: Pregătiţi-vă imaginile în produse „fără defecte” şi „cu defecte”

- Adnotarea: Marcaţi defectele ca şi cum le-aţi indica unei alte persoane.

- Învăţarea: Pur şi simplu începeţi procesul de învăţare automată, iar configurarea va fi completă în câteva minute.

Eliminarea detectării în exces

- Algoritm avansat pe bază de inteligenţă artificială: Reduce falsurile pozitive cauzate de variaţiile de formă, culoare şi luciu.

- Tehnologie de instruire automată: Instruieşte rapid modelul cu imagini minime, asigurând rezultate fiabile şi reproductibile.

- Prelucrare în funcţie de context: Detectează numai defectele semnificative, ignorând zgomotul de fond irelevant

De încredere în diverse industrii

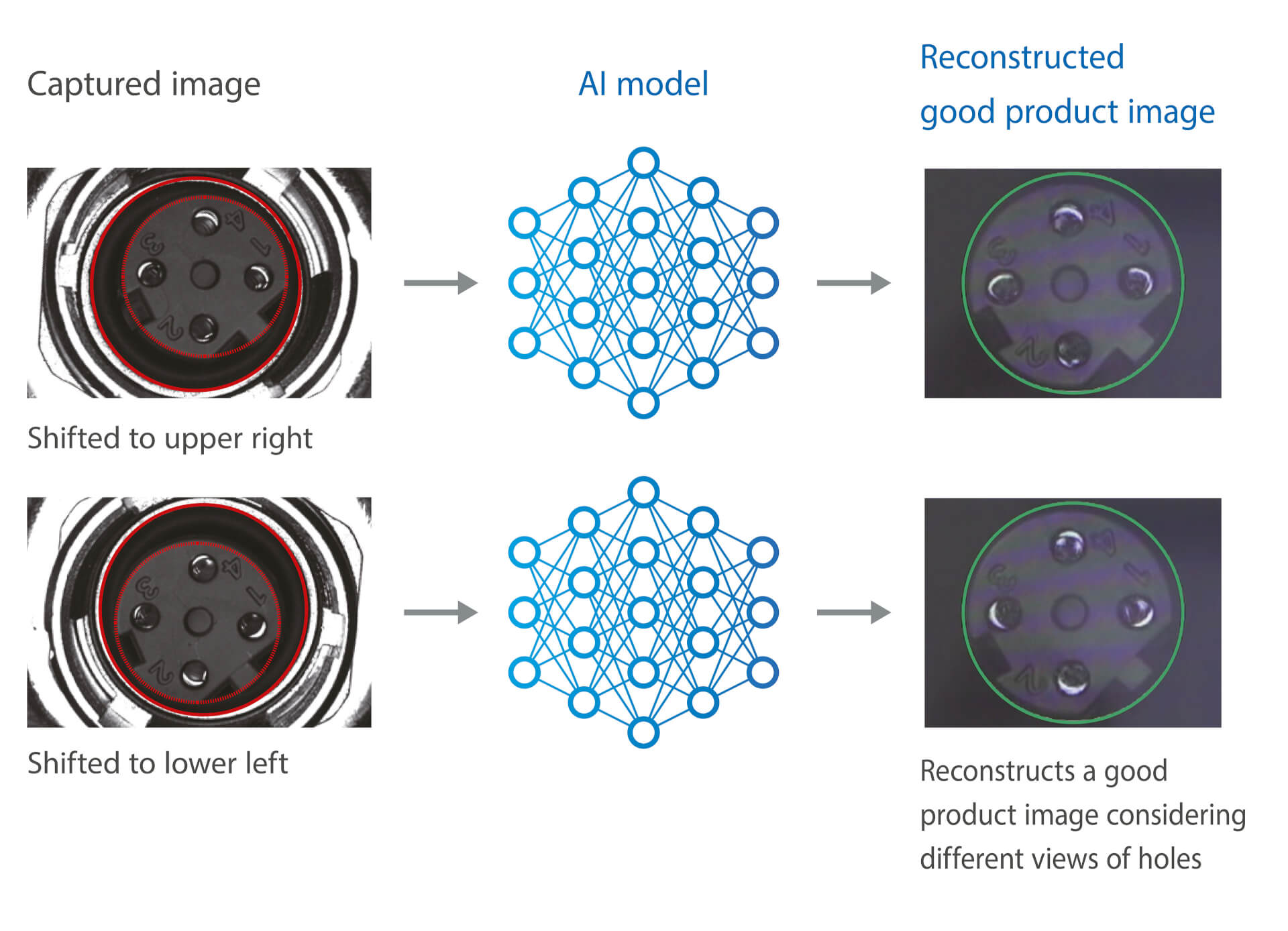

Potrivire fină cu inteligenţa artificială

Potrivirea fină cu inteligenţa artificială identifică o caracteristică ce nu este inclusă în produsele bune ca defect. Inteligenţa artificială învaţă imagini ale produselor bune cu variaţii şi generează un model de inteligenţă artificială. De fiecare dată când se efectuează o inspecţie, inteligenţa artificială reconstruieşte un model despre care se presupune că este un produs bun. Inteligenţa artificială extrage o diferenţă între imaginea bună a produsului reconstruit şi o imagine capturată pentru a identifica un defect, reducând supradetectarea.

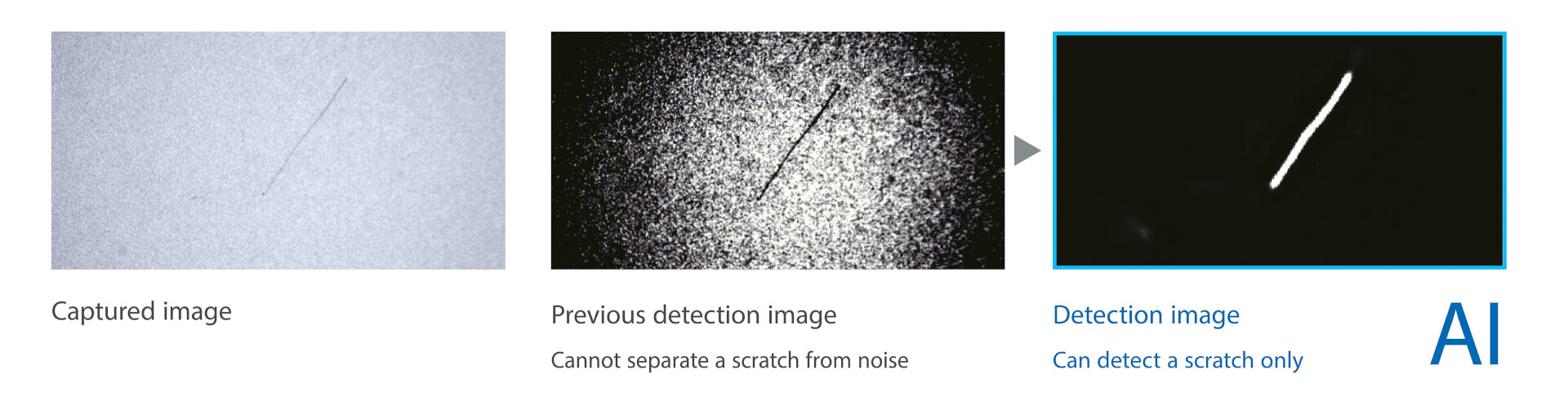

Defect de la zeto cu inteligenţa artificială

Cele mai recente capacităţi ale sistemului de inspecţie cu cameră video FH includ un filtru de imagine bazat pe inteligenţa artificială, care reproduce tehnica utilizată de inspectorii calificaţi pentru a identifica un defect pe orice fundal de produs. Zgârieturile şi petele care erau cândva dificil de capturat pot fi acum identificate chiar şi fără utilizarea probelor sau ajustare

Aplicaţii

Îmbunătăţirea detectării cu ajutorul camerelor Linescan

Camerele Linescan au un avantaj semnificativ faţă de camerele Area Scan atunci când vine vorba de obiecte mari, cilindrice sau în continuă mişcare. FH acceptă conectarea a până la 4 camere Linescan cu rezoluţie de la 2K la 8K.

Soluţii optimizate cu imagistica Linescan

Liniile de producţie în mişcare rapidă, obiectele curbate sau cilindrice sau aplicaţiile cu spaţiu limitat sunt ideale pentru imagistica Linescan. Aplicaţiile obişnuite includ:

- Inspectarea etichetelor produselor cilindrice care necesită inspecţie.

- Inspecţii continue pe aplicaţii de ridicare şi plasare sau pe aplicaţii de numărare.

- Inspectarea defectelor/suprafeţei bateriilor EV care necesită inspecţie pe întreaga suprafaţă a piesei.

Sistem de inspecţie cu cameră video pregătit pentru a fi conform cu CFR Titlul 21, Partea a 11-a şi GMP

Sistemul de inspecţie cu cameră video din seria FH poate fi actualizat pentru a asigura conformitatea cu CFR Titlul 21, Partea a 11-a şi GMP, permiţându-le fabricanţilor de produse din domeniul ştiinţelor vieţii, farmaceutice şi medicale să instaleze, în cadrul liniei lor de producţie, sisteme de inspecţie cu cameră video care să fie conforme cu aceste reglementări.

Funcţii software

- Raport jurnal de audit

- Instrument de vizualizare jurnal de audit

- Securitate parolă îmbunătăţită

- Fişiere criptate

- Controale acces utilizatori

- Pregătire pentru autentificare unică

- Integrare HMI

Decodare filigran digital Digimarc

Decodificare fără pereche pe ambalaje cilindrice şi flexibile

Inspecţia aspectului celulelor bateriei reîncărcabile

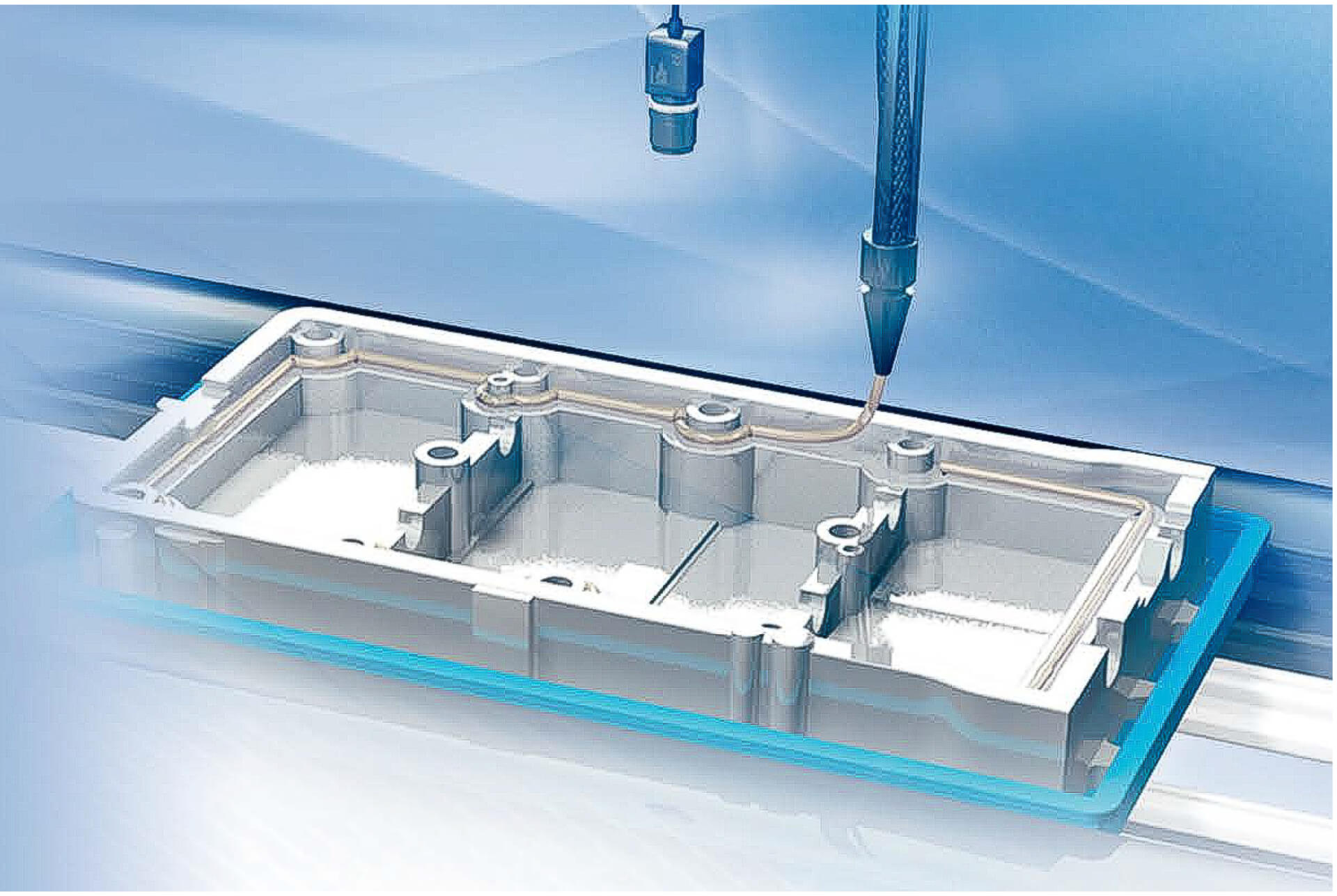

Inspecţie picături de adeziv

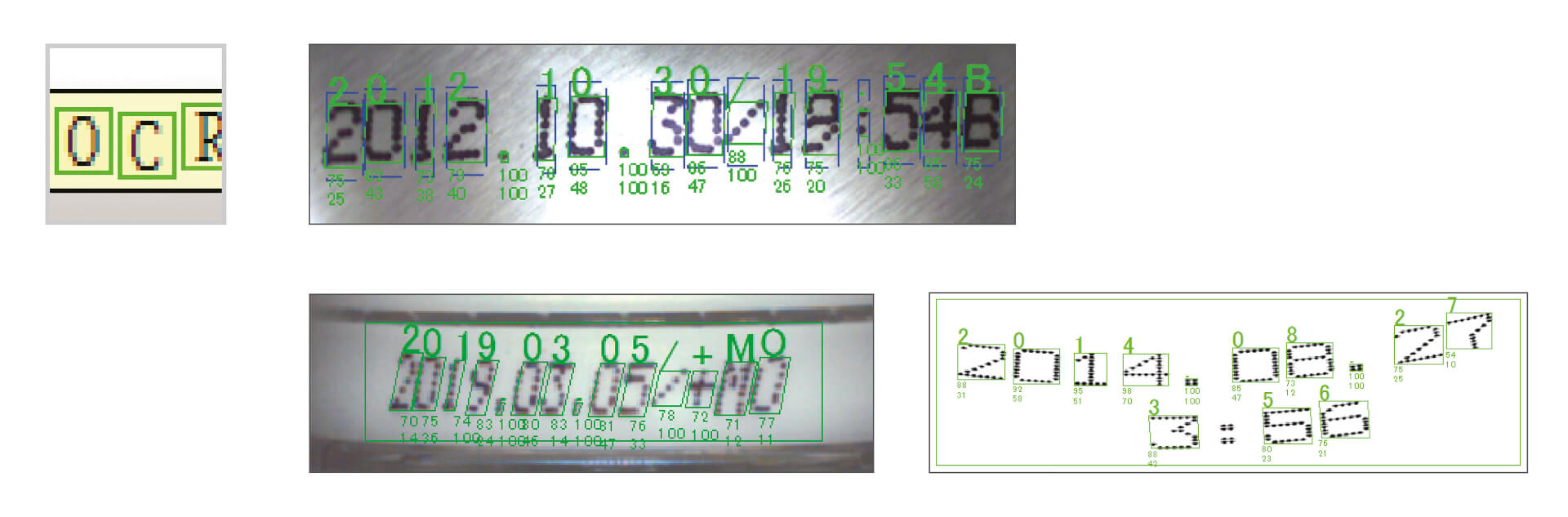

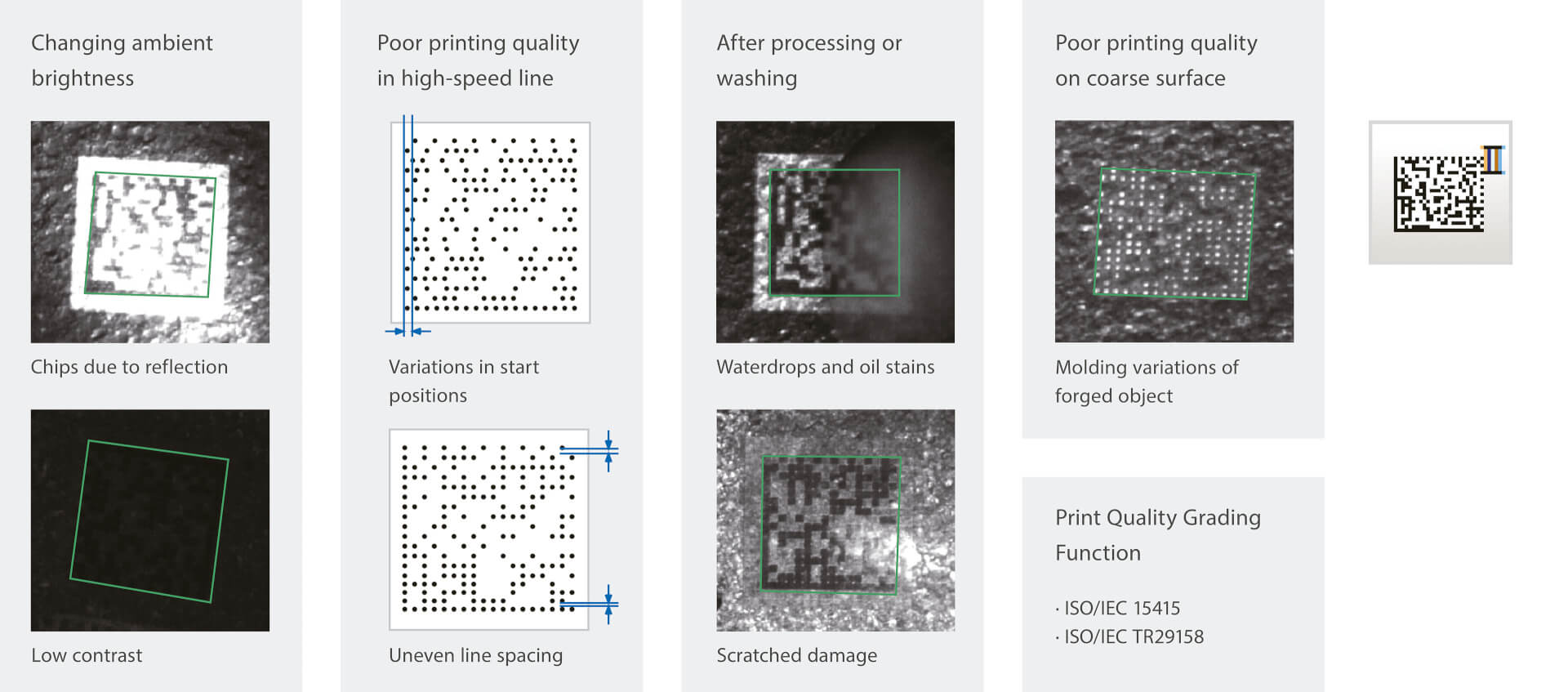

Citiţi cu încredere caracterele greu de citit

Lens Selector

Videoclipuri

-

FH Vision System from OMRON: AI defect inspection for chips on glass bottles

Stable detection of just the defects, even with workpiece gloss variations.

03:07

FH Vision System from OMRON: AI defect inspection for chips on glass bottles

Stable detection of just the defects, even with workpiece gloss variations.

-

FH Vision System: AI defect inspection of laminated battery tab welding

Stable detection of just the defects, even with workpiece gloss variations.

02:44

FH Vision System: AI defect inspection of laminated battery tab welding

Stable detection of just the defects, even with workpiece gloss variations.

-

FH Vision System from OMRON: AI defect inspection of stator powder coating

Stable detection of just the defects, even with workpiece gloss variations.

03:08

FH Vision System from OMRON: AI defect inspection of stator powder coating

Stable detection of just the defects, even with workpiece gloss variations.

-

3 Step Easy Configuration of AI Defect Inspection FH Vision System from OMRON

OMRON has created the AI defect inspection feature that is easy to use for anyone.

02:47

3 Step Easy Configuration of AI Defect Inspection FH Vision System from OMRON

OMRON has created the AI defect inspection feature that is easy to use for anyone.Specificaţii şi informaţii pentru comenzi

| Produs | Performance | Processor family | Operating system | Memory | AI Scratch detection filter | AI FineMatching | Number of cameras | Integrated monitor | Communication port(s) | Output type | Application | Descriere | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (ECC) | No | No | 4 | No | EtherCAT Slave, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 2 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH-Lite controller, standard grade, box type, 2 camera, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 4 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Counting, Defect inspection, Measurement inspection, OCR / OCV | FH-Lite controller, standard grade, box type, 4 camera, , W10 IoT Enterprise LTSC 2019 64bit |

|

Noul sistem de inspecţie FH cu tehnologie pe bază de inteligenţă artificială pentru detectarea defectelor

Sistemul de procesare a imaginilor identifică defectele subtile cu o acuitate similară celei umane, pentru cerinței ridicate de detecție a defectelor.

Suntem aici pentru a vă ajuta

Aveţi o întrebare? Specialiştii noştri sunt pregătiţi să vă ajute la fiecare pas al parcursului.

Contactați-mă Sistem FH de inspecţie cu cameră video

Vă mulțumim pentru solicitarea trimisă. Vom reveni cu un răspuns cât mai curând posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadOfertă pentru Sistem FH de inspecţie cu cameră video

Prin completarea acestui formular puteţi face o cerere de ofertă. Vã rugãm completaţi toate câmpurile marcate cu *. Datele dumneavoastrã personale vor fi tratate cu confidențialitate.

Vă mulțumim pentru cererea de ofertă trimisă. Vă vom oferi informațiile cerute în cel mai scurt timp posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadDescărcări

Vă rugăm să vă conectaţi sau înregistrare la conţinutul de pe această pagină.

Vă rugăm să vă conectaţi sau înregistrare la conţinutul de pe această pagină.

Vă rugăm să vă conectaţi sau înregistrare la conţinutul de pe această pagină.

Produse conexe

Aveţi nevoie de asistenţă?

Suntem aici pentru a vă ajuta! Contactaţi-ne, iar specialiştii noştri vă vor ajuta să găsiţi cea mai bună soluţie pentru afacerea dvs.

Contactați-mă Sistem FH de inspecţie cu cameră video

Vă mulțumim pentru solicitarea trimisă. Vom reveni cu un răspuns cât mai curând posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadOfertă pentru Sistem FH de inspecţie cu cameră video

Prin completarea acestui formular puteţi face o cerere de ofertă. Vã rugãm completaţi toate câmpurile marcate cu *. Datele dumneavoastrã personale vor fi tratate cu confidențialitate.

Vă mulțumim pentru cererea de ofertă trimisă. Vă vom oferi informațiile cerute în cel mai scurt timp posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

Download