Camere FH

Portofoliul de camere FH pentru inspecţie video – camera potrivită pentru a satisface fiecare aplicaţie

Această linie de produse reprezintă o gamă completă de camere de scanare de zonă pentru a satisface fiecare aplicaţie din orice industrie care utilizează inspecţia video. Camere în miniatură extrem de compacte, cu iluminare integrată şi set complet de camere cu montare C şi M42 de până la 21 Mpix. Toate conectabile la puternicul controler FH/FZ5 pentru inspecţie video; trebuie doar să conectaţi şi sunteţi gata.

-

Vision System FH series

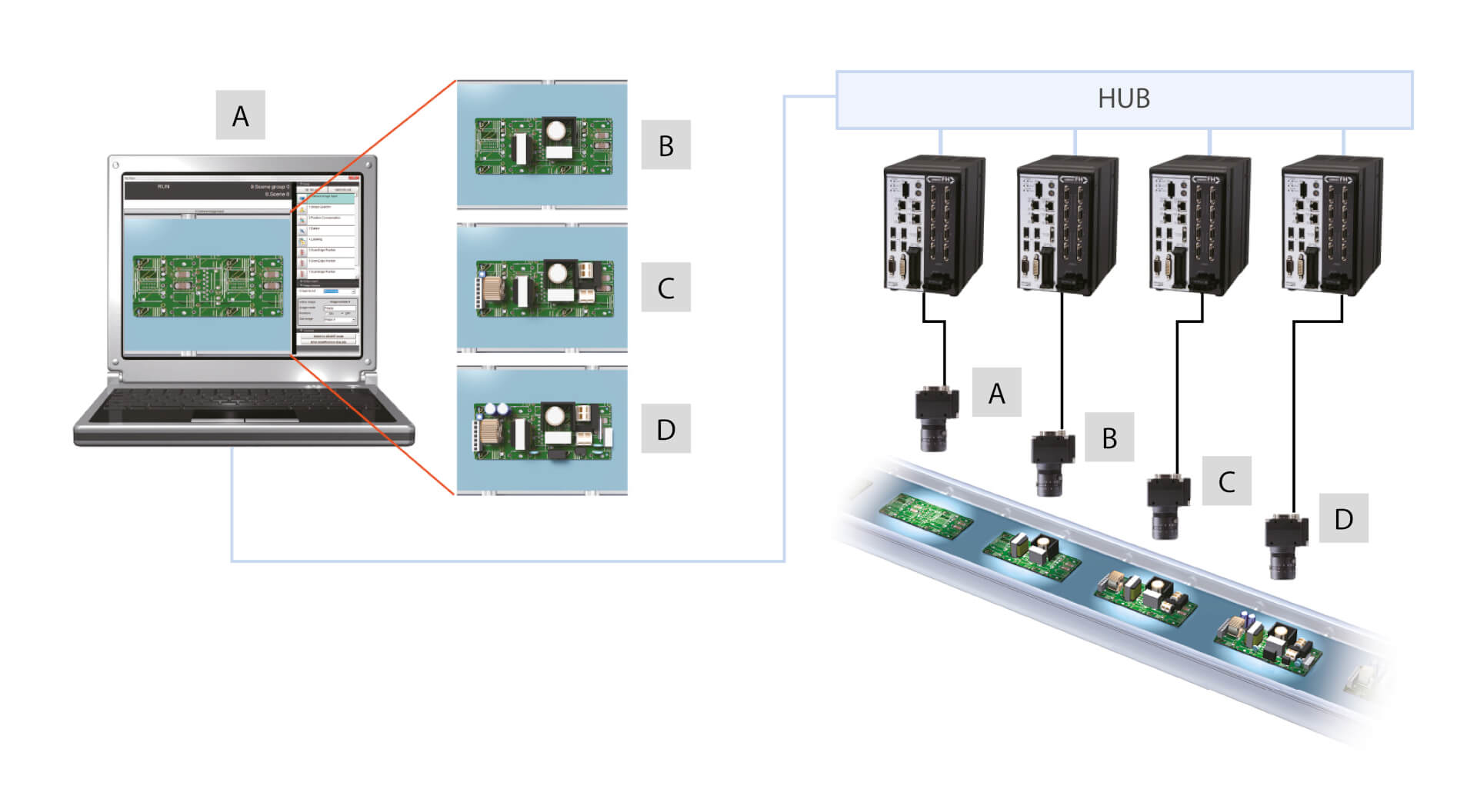

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.

02:05

Vision System FH series

The FH-series Vision System provides higher speed and precision for Machine cycle time and is loaded with all of the performance required to move Machines quickly and at high precision into a compact Controller for embedding into Machine. And even though the Camera/communications interfaces, image processing algorithms, and other features of this complete image processing system are built into one housing, the flexibility of a PC-based image processing system is also provided to help increase eciency in the frequent reuse of Machine designs and in design changes.O serie completă de camere pentru diferite aplicaţii

Noul sistem de inspecţie FH cu tehnologie pe bază de inteligenţă artificială pentru detectarea defectelor

Sistemul de procesare a imaginilor identifică defectele subtile cu o acuitate similară celei umane, pentru cerinței ridicate de detecție a defectelor.

Caracteristici

O serie completă de camere pentru diferite aplicaţii

Funcţionare mai rapidă a aparatelor

Integrare uşoară software şi hardware

Tehnologie de detecție ultra-high-speed într-un design compact

Camerele inteligente FH/FZ proiectate pentru utilizare în toate tipurile de operațiuni pentru măsurare, poziționare/orientare și inspecție de obiecte, această cameră compactă și sistemul de controler este ușor integrat în aproape orice dispozitiv sau robot. Sistemul are capacitatea unică de a oferi rezultate mai rapide și mai precise, aducându-vă costuri mai mici, eficiență sporită și nu doar atât.

Soluții inovatoare de iluminare

- MDMC Light vă permite să modificaţi liber culoarea şi modelul de direcţie în milisecunde. Puteţi alege cel mai bun model prin combinarea direcţiilor de iluminare x RGB cu culori complete x 128 de niveluri de luminozitate de 13 blocuri

- Nu este necesar schimbul de componente în timpul înlocuirii produselor.

- Îmbunătăţiţi funcţionalitatea de inspecţie pe care o căutaţi – uşor, rapid şi fiabil

- Combinaţi sute de corpuri de iluminat într-o singură unitate

- PMS Light permite sistemului dvs. de inspecţie să vizualizeze ceea ce numai cel mai inteligent instrument optic – ochiul uman – poate vedea

- Măreşte rata inspecţiei video automate – fiabilă, repetabilă şi productivă

- Creează cele mai robuste soluţii de inspecţie cu cameră video, inclusiv pe suprafeţe extrem de dificile

Sistemul FH de inspecţie cu cameră video este compatibil cu protocoalele de comunicaţii cele mai moderne, mai rapide şi cu cea mai largă acceptare la nivel industrial – acum şi ProfiNet

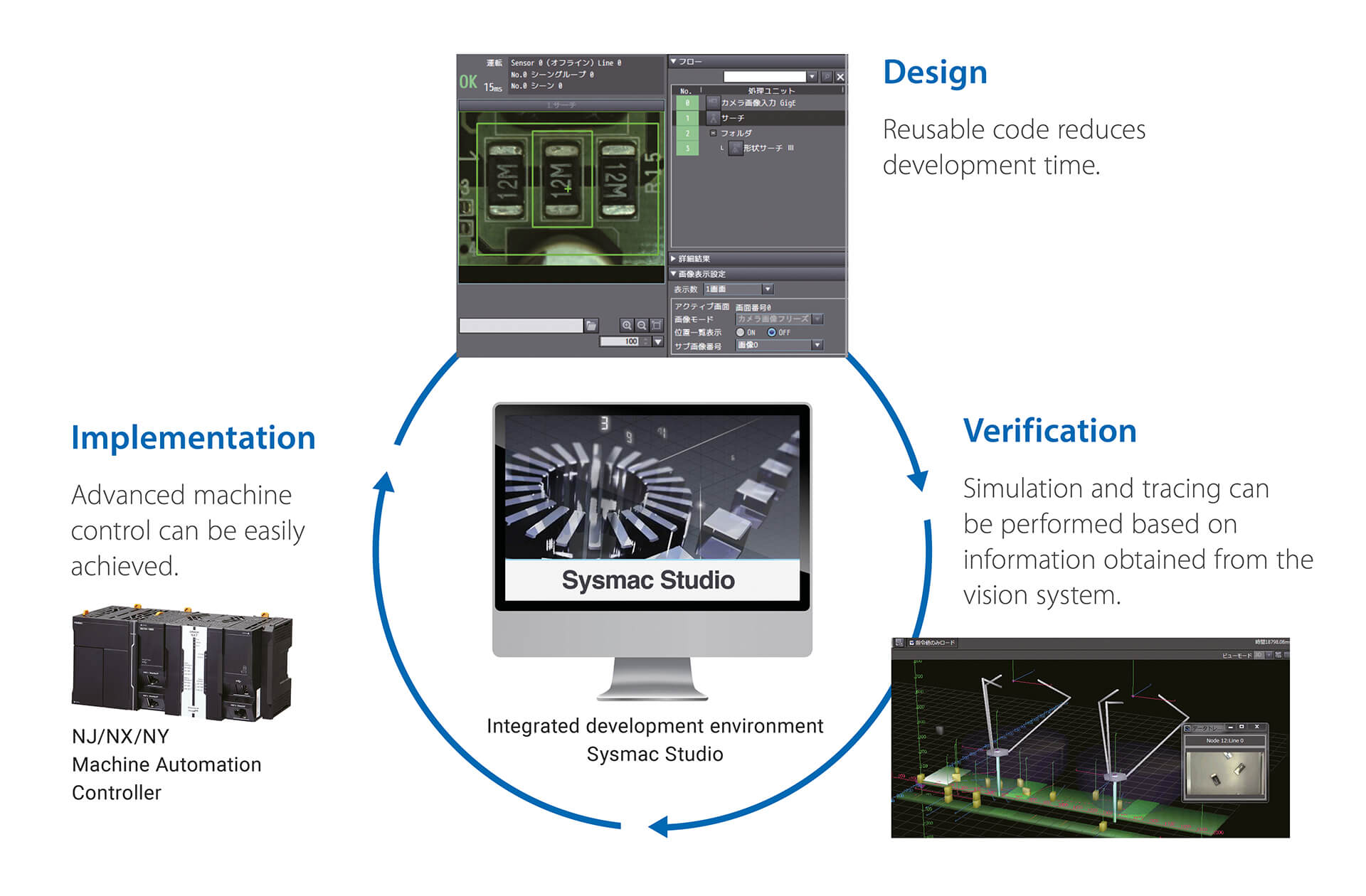

Profitând de platforma OMRON Sysmac, integrarea unui sistem de inspecţie cu cameră video în mașina dvs. nu a fost niciodată mai uşoară. Nu numai că ştim să vă inspectăm produsul – ci îl putem muta, controla şi putem proiecta soluţia completă în jurul procesului şi producţiei dvs. Fie că vă ajutăm să efectuaţi o singură inspecţie sau să controlaţi o linie de producţie completă, la fiecare pas, atenţia noastră se concentrează asupra unei arhitecturi clare şi inteligibile, care vă uşurează viaţa şi vă îmbunătăţeşte productivitatea.

-

1ProiectCodul refolosibil reduce timpul de dezvoltare.

-

2VerificareSimularea și monitorizarea se pot efectua în funcție de informațiile obținute de la sistemul de inspecție vizuală.

-

3ImplementareControlul avansat al mașinilor poate fi obținut cu ușurință.

Aplicaţii

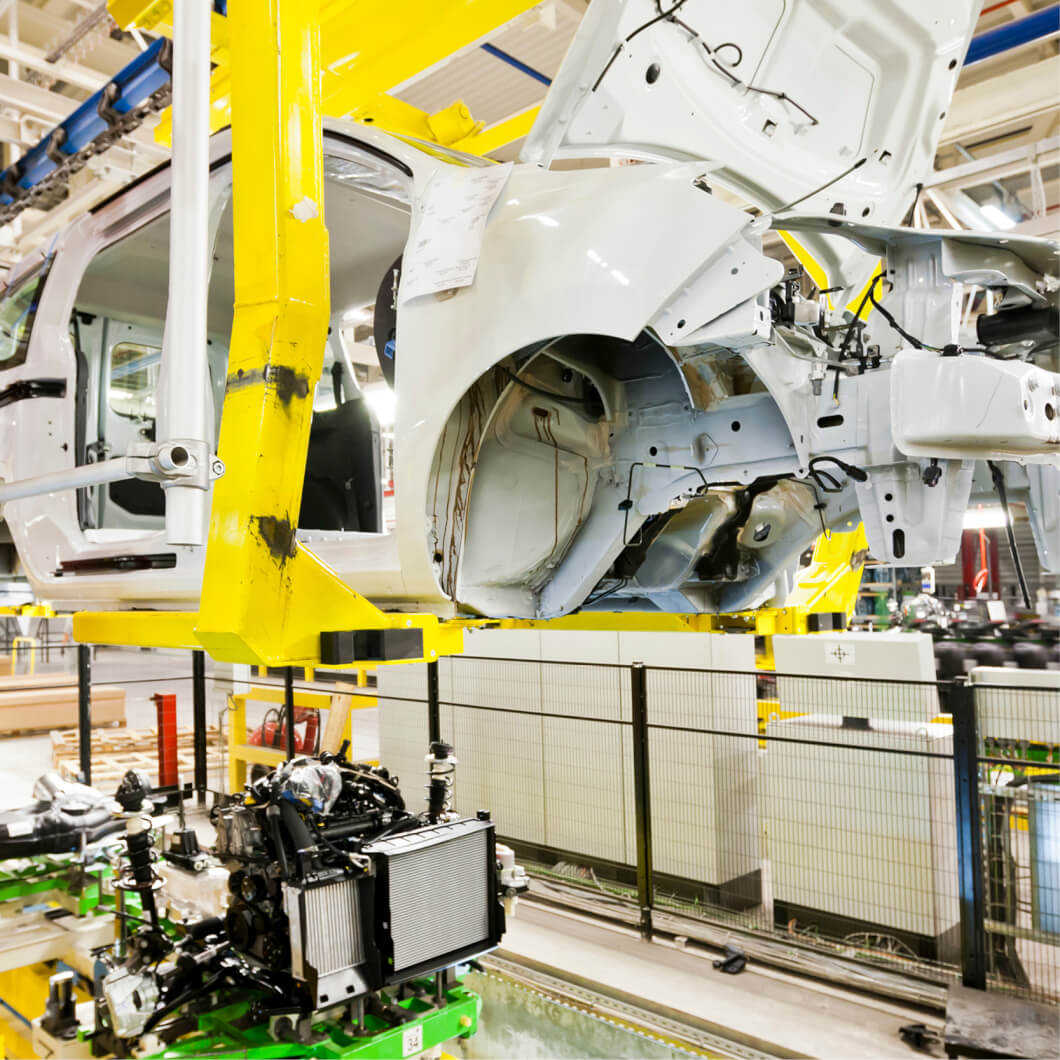

Industria auto

- Linii de asamblare

- Linii de inspecţie și controlul calităţii

- Inspecție produse cosmetice

- Aplicații de măsurare de mare acuratețe

Alimente și bunuri

- Inspecţia calităţii

- Linii de umplere cu lichid/pudră

- Ambalare primară sau secundară

- Alegere și plasare

Scopuri de trasabilitate

- Inspecția etichetelor și a imprimării

- Aplicații de urmărire

Videoclipuri

-

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

05:58

Omron's FH vision system helps improve efficiency and quality in production lines

Automated sensory inspection has been a challenge for automation for years Automation inspections are introduced to find scratches and dents on products, but these may overlook unexpected defects or recognize light stains as defects and over detect defective products. Over detection leads to secondary human inspections as well as overlooked products escape to post-processes decreasing yields. The introduction to automated sensory inspections takes time, resources, and expertise. Omron solves these issues through its vision sensors using Artificial Intelligence (AI) technologies. The FH Vision System Series reproduces human sensibility and experience with AI technology. The FH Vision System Series has an inspection algorithm using AI or AI Fine Matching installed. AI Fine Matching detects only the features not found on good products as defects. Training with images of various good products builds an AI model that helps automate inspection processes. The more the various good images you provide, the better the inspection accuracy. In this way, the AI model learns about variation in the shape and color of good products. An AI model misses no tiny scratch or dent. The AI Fine Matching enables streamlining the inspection flow and reduces the number of inspections preventing overdetection and wasteful secondary inspections. AI Fine Matching improves yields by preventing the overlook of defective products that escape to post-processes. Learn more about FH Vision System Series:

-

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:56

Cap Inspection | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. An automated inspection system may over detect by flagging good products as defective under strict criteria to prevent defective products from being marketed. The implementation of automated inspection requires adjustment for different bottles and caps. Because the transfer of setup and adjustment knowledge to other inspection lines hinders the adoption of automated inspection, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

05:58

AI Fine Matching | FH-series Vision System

Automated sensory inspection has been extremely difficult to automate for a long time. Do you have any concern about missing defects or overdetecting them in your visual inspection process? An automated inspection system designed to find scratches and dents on products may overlook other types of defects that are unexpected. Because the implementation of automated inspection can be time-consuming and typically requires specialized knowledge, many manufacturers give up on the idea. OMRON solves these issues by combining its powerful vision sensors with artificial intelligence. The FH-series vision system reproduces human sensibility and experience with AI technology. By training upon images of various good products, the system builds an AI model. The FH-series suggests training images and assists with the construction of a workable AI model in the shortest period of time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

2D Robot Vision System| FH-series Vision System

Manufacturers increasingly need automation and labour-saving solutions to prevent infection and overcome the labour shortage. Are you considering automating transfer and assembly with robot vision systems at your manufacturing site? OMRON offers the perfect solution for you, the FH-series Vision System. The FH Series can be easily connected to various robots. Automated transfer and assembly and advanced inspection can be performed simultaneously. OMRON offers a 2D robot vision system solution. A vision system program and robot program need to be prepared to connect a vision system to a robot. OMRON provides these programs for easy implementation. Programs for pick, grip correction, place and combined applications are available. The FH Series can be mounted on a robot hand or arm. The FH-series Vision System enables automated transfer and assembly and advanced inspection at the same time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

04:37

2D Robot Vision System| FH-series Vision System

Manufacturers increasingly need automation and labour-saving solutions to prevent infection and overcome the labour shortage. Are you considering automating transfer and assembly with robot vision systems at your manufacturing site? OMRON offers the perfect solution for you, the FH-series Vision System. The FH Series can be easily connected to various robots. Automated transfer and assembly and advanced inspection can be performed simultaneously. OMRON offers a 2D robot vision system solution. A vision system program and robot program need to be prepared to connect a vision system to a robot. OMRON provides these programs for easy implementation. Programs for pick, grip correction, place and combined applications are available. The FH Series can be mounted on a robot hand or arm. The FH-series Vision System enables automated transfer and assembly and advanced inspection at the same time. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

Connector Inspection Function | FH-series Vision System and Cameras

The OMRON Connector Inspection Function in the FH-series integrates settings required for pin position detection and allows users to perform complicated dimensional inspections like coplanarity inspection just by selecting inspection items. A search model can be shared between different types of connectors, reducing configuration time when new types are added. Just change the number if inspection areas for connectors with different numbers of pins to complete adjustment. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

03:56

Connector Inspection Function | FH-series Vision System and Cameras

The OMRON Connector Inspection Function in the FH-series integrates settings required for pin position detection and allows users to perform complicated dimensional inspections like coplanarity inspection just by selecting inspection items. A search model can be shared between different types of connectors, reducing configuration time when new types are added. Just change the number if inspection areas for connectors with different numbers of pins to complete adjustment. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

-

AI Filter | FH-series Vision System

OMRON is using artificial intelligence to reproduce the visual sensitivity and experience of human inspectors. The AI filter detects scratches with human-like sensitivity. Using an AI filter equipped with defect extraction technology, only the points that are estimated to be scratches with be automatically extracted. The AI algorithms extract the scratch itself, rather than the definition based on colour and brightness. This makes defect detection much more stable flaw. The AI filter eliminates missed defects and AI Fine Matching avoids overdetection almost entirely. No special environment construction or expertise required. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:

03:03

AI Filter | FH-series Vision System

OMRON is using artificial intelligence to reproduce the visual sensitivity and experience of human inspectors. The AI filter detects scratches with human-like sensitivity. Using an AI filter equipped with defect extraction technology, only the points that are estimated to be scratches with be automatically extracted. The AI algorithms extract the scratch itself, rather than the definition based on colour and brightness. This makes defect detection much more stable flaw. The AI filter eliminates missed defects and AI Fine Matching avoids overdetection almost entirely. No special environment construction or expertise required. OMRON offers the best combination of camera and controller for your inspection systems in terms of precision, speed and cost. The FH-series vision system reproduces human sensibility and experience with AI technology. Learn more about FH-series Vision System here: Learn more about FH Smart Cameras here:Specificaţii şi informaţii pentru comenzi

| Produs | Number of pixels | Focus distance | Autofocus | Camera family | Camera type | Frame rate | Illumination | Image width | Image height | Scan type | Shutter type | Image sensor format | Image sensor type | Lens mount | Lens type | Pixel size | Degree of protection (IP) | Descriere | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

2.0 MP | No | FH | Color | 219 fps | None | 2040 pixels | 1088 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | FH camera, high resolution 2M pixel, color |

|

|

|

|

4.0 MP | No | FH | Color | 118 fps | None | 2040 pixels | 2048 pixels | Area scan | Global | 1" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | FH camera, high resolution 4M pixel, color |

|

|

|

|

5.0 MP | No | FH | Color | 14 fps | None | 2592 pixels | 1944 pixels | Area scan | Rolling | 1/2.5" | CMOS | C-mount | Not Applicable | 2.2 µm | IP10 | FH camera, high resolution 5 m pixel, color, rolling shutter |

|

|

|

|

20.4 MP | No | FH | Color | 25.6 fps | None | 5544 pixels | 3692 pixels | Area scan | Rolling | 1" | CMOS | C-mount | Not Applicable | 2.4 µm | IP10 | FH Camera, high speed, 20.4 MPixel, c-Mount, rolling shutter, color |

|

|

|

|

0.4 MP | No | FH | Color | 523.6 fps | None | 720 pixels | 540 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 6.9 µm | IP10 | FH Camera, high speed, 0.4 MPixel, c-Mount, global shutter, color |

|

|

|

|

1.6 MP | No | FH | Color | 154.6 fps | None | 1440 pixels | 1080 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 1.6 MPixel, C-Mount, global shutter, colour |

|

|

|

|

3.2 MP | No | FH | Color | 151.4 fps | None | 2046 pixels | 1536 pixels | Area scan | Global | 1/1.8" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 3.2 MPixel, C-Mount, global shutter, colour |

|

|

|

|

5.0 MP | No | FH | Color | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH Camera, high speed, 5 MPixel, c-Mount, global shutter, color |

|

|

|

|

12 MP | No | FH | Color | 40.1 fps | None | 4092 pixels | 3000 pixels | Area scan | Global | 1.1" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH Camera, high speed, 12 MPixel, C-Mount, global shutter, color |

|

|

|

|

0.3 MP | No | FH | Monochrome | 308 fps | None | 640 pixels | 480 pixels | Area scan | Global | 1/3" | CMOS | C-mount | Not Applicable | 7.4 µm | IP10 | FH camera, standard resolution, monochrome |

|

|

|

|

2.0 MP | No | FH | Monochrome | 219 fps | None | 2040 pixels | 1088 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | FH camera, high resolution 2M pixel, monochrome |

|

|

|

|

4.0 MP | No | FH | Monochrome | 118 fps | None | 2040 pixels | 2048 pixels | Area scan | Global | 1" | CMOS | C-mount | Not Applicable | 5.5 µm | IP10 | FH camera, high resolution 4M pixel, monochrome |

|

|

|

|

5.0 MP | No | FH | Monochrome | 14 fps | None | 2592 pixels | 1944 pixels | Area scan | Rolling | 1/2.5" | CMOS | C-mount | Not Applicable | 2.2 µm | IP10 | FH camera, high resolution 5 m pixel, monochrome, rolling shutter |

|

|

|

|

20.4 MP | No | FH | Monochrome | 25.6 fps | None | 5544 pixels | 3692 pixels | Area scan | Rolling | 1" | CMOS | C-mount | Not Applicable | 2.4 µm | IP10 | FH Camera, high speed, 20.4 MPixel, c-Mount, rolling shutter, monochrome |

|

|

|

|

0.4 MP | No | FH | Monochrome | 523.6 fps | None | 720 pixels | 540 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 6.9 µm | IP10 | FH Camera, high speed, 0.4 MPixel, c-Mount, global shutter, monochrome |

|

|

|

|

0.3 MP | No | FH | Monochrome, SWIR | 240 fps | None | 640 pixels | 512 pixels | Area scan | Global | 1/4" | IMX991 | C-mount | Not Applicable | 5.0 µm | IP40 | FH SWIR Camera, 0.3 MPixel, C-Mount, global shutter, monochrome |

|

|

|

|

1.6 MP | No | FH | Monochrome | 154.6 fps | None | 1440 pixels | 1080 pixels | Area scan | Global | 1/2.9" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 1.6 MPixel, C-Mount, global shutter, monochrome |

|

|

|

|

1.3 MP | No | FH | Monochrome, SWIR | 120 fps | None | 1280 pixels | 1024 pixels | Area scan | Global | 1/2" | IMX990 | C-mount | Not Applicable | 5.0 µm | IP40 | FH SWIR Camera,1.3 MPixel, C-Mount, global shutter, monochrome |

|

|

|

|

3.2 MP | No | FH | Monochrome | 151.4 fps | None | 2046 pixels | 1536 pixels | Area scan | Global | 1/1.8" | CMOS | C-mount | Not Applicable | 3.45 µm | IP40 | FH Camera, high speed, 3.2 MPixel, C-Mount, global shutter, monochrome |

|

|

|

|

5.0 MP | No | FH | Monochrome | 97.2 fps | None | 2448 pixels | 2048 pixels | Area scan | Global | 2/3" | CMOS | C-mount | Not Applicable | 3.45 µm | IP10 | FH Camera, high speed, 5 MPixel, c-Mount, global shutter, monochrome |

|

Suntem aici pentru a vă ajuta

Aveţi o întrebare? Specialiştii noştri sunt pregătiţi să vă ajute la fiecare pas al parcursului.

Contactați-mă Camere FH

Vă mulțumim pentru solicitarea trimisă. Vom reveni cu un răspuns cât mai curând posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadOfertă pentru Camere FH

Prin completarea acestui formular puteţi face o cerere de ofertă. Vã rugãm completaţi toate câmpurile marcate cu *. Datele dumneavoastrã personale vor fi tratate cu confidențialitate.

Vă mulțumim pentru cererea de ofertă trimisă. Vă vom oferi informațiile cerute în cel mai scurt timp posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadDescărcări

Produse conexe

Aveţi nevoie de asistenţă?

Suntem aici pentru a vă ajuta! Contactaţi-ne, iar specialiştii noştri vă vor ajuta să găsiţi cea mai bună soluţie pentru afacerea dvs.

Contactați-mă Camere FH

Vă mulțumim pentru solicitarea trimisă. Vom reveni cu un răspuns cât mai curând posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadOfertă pentru Camere FH

Prin completarea acestui formular puteţi face o cerere de ofertă. Vã rugãm completaţi toate câmpurile marcate cu *. Datele dumneavoastrã personale vor fi tratate cu confidențialitate.

Vă mulțumim pentru cererea de ofertă trimisă. Vă vom oferi informațiile cerute în cel mai scurt timp posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

Download

_instruction_sheet_en.jpg)

_-_image_processing_system_instruction_sheet_en.jpg)