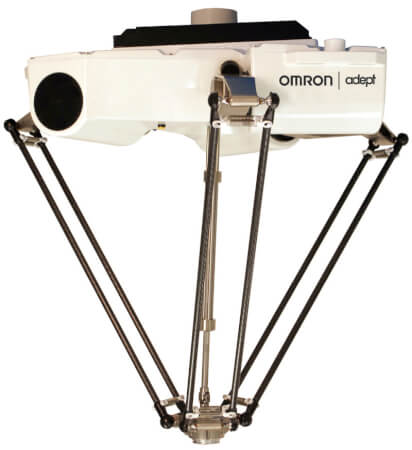

Hornet

Robot paralel ideal pentru utilizarea în industria alimentară şi a băuturilor, farmaceutică şi de îngrijire a sănătăţii

- Capabilitate de control a roboţilor prin Ethernet cu ajutorul limbajului de programare familiar (IEC 61131-3) al controlerului de utilaj NX/NJ

- Amplificatorul şi controlerul încorporate în robot reduc numărul de cabluri

- Urmăreşte până la o viteză a benzii transportoare de 1,4 m/s

- Conceput cu o sarcină utilă ridicată, pentru a susţine ridicarea cu mai multe mâini (ridicarea multiplă)

- Contribuie la reducerea costurilor de montare şi a vibraţiilor robotului

- Domeniu de lucru de 1.130 mm

- Până la o sarcină utilă max. de 8 kg

- Clasă de protecţie IP65

Specificaţii şi informaţii pentru comenzi

| Produs | Payload | Reach | Robot controller | Z-Stroke | Degree of protection (IP) | Rotation -/+ | Degrees of freedom | Descriere | |

|---|---|---|---|---|---|---|---|---|---|

|

|

3 kg | 565 mm | Not required | 425 mm | IP20 | 360 ° | 4 | Hornet 565, 3 kg payload, 565mm reach, 360º rotation, 4 axis, 425mm Zaxis, IP20, ePLC |

|

|

|

8 kg | 565 mm | Not required | 425 mm | IP65 | 0 ° | 3 | Hornet 565, 8 kg payload, 565mm reach, 0º rotation, 3 axis, 425mm Zaxis, IP65, ePLC |

|

|

|

3 kg | 565 mm | Not required | 425 mm | IP65 | 360 ° | 4 | Hornet 565, 3 kg payload, 565mm reach, 360º rotation, 4 axis, 425mm Zaxis, IP65, ePLC |

|

|

|

8 kg | 565 mm | EX Controller | 425 mm | IP20 | 0 ° | 3 | Hornet 565, Add-On, 8 kg payload, 565mm reach, 0º rotation, 3 axis, 425mm Zaxis, IP20, ePLC |

|

|

|

3 kg | 565 mm | EX Controller | 425 mm | IP20 | 360 ° | 4 | Hornet 565, Add-On, 3 kg payload, 565mm reach, 360º rotation, 4 axis, 425mm Zaxis, IP20, ePLC |

|

|

|

8 kg | 565 mm | EX Controller | 425 mm | IP65 | 0 ° | 3 | Hornet 565, Add-On, 8 kg payload, 565mm reach, 0º rotation, 3 axis, 425mm Zaxis, IP65, ePLC |

|

|

|

3 kg | 565 mm | EX Controller | 425 mm | IP65 | 360 ° | 4 | Hornet 565, Add-On, 3 kg payload, 565mm reach, 360º rotation, 4 axis, 425mm Zaxis, IP65, ePLC |

|

Accesorii

Ordering information

| Apperance | Type | Name/Specifications | Order code |

|---|---|---|---|

|

Robot Integrated Controller | 16 motion axis, up to 8 robots control | NJ501-R300 |

| 32 motion axis, up to 8 robots control | NJ501-R400 | ||

| 64 motion axis, up to 8 robots control | NJ501-R500 | ||

|

Robot Controller | SmartController EX | 19200-000 |

| SmartController EX + Front Panel | 19300-000 | ||

|

Pendant | T20 Pendant with 10 m Cable | 10046-010 |

| T20 Pendant-Jumper Plug | 10048-000 | ||

| T20 Pendant Wall Bracket | 10079-000 | ||

| T20 Adapter Cable, 3 m | 10051-003 | ||

|

Vision Controller | IPC Application Controller | AC1-152000 |

|

Camera | GigE PoE, 1602 x 1202 pixels, 60 fps, Monochrome, CMOS (1/1.8-inch equivalent), camera cables included (10 m) | 24114-250 |

| GigE PoE, 1602 x 1202 pixels, 60 fps, Color, CMOS (1/1.8-inch equivalent), camera cables included (10 m) | 24114-251 | ||

| GigE PoE, 2048 x 2048 pixels, 25 fps, Monochrome, CMOS (1-inch equivalent), camera cables included (10 m) | 24114-300 | ||

| GigE PoE, 2048 x 2048 pixels, 25 fps, Color, CMOS (1-inch equivalent), camera cables included (10 m) | 24114-301 | ||

| Belt Encoder (Conveyor-Tracking) |

Encoder Kit IP65 | 09742-001 | |

| Y-Adapter Cable, 3 m | 09443-000 | ||

| Encoder Extension Cable, 5 m | 09446-050 | ||

| SCEX-BELT,Y-Adapter Cable, 0.5 m | 09550-000 | ||

| XBELTIO Cable, 0.6 m | 13463-000 | ||

| Additional I/O Options | IO Blox (connect to robot), 8 inputs/8 outputs, cables included (0.3 m) | 90356-30200 | |

| IO Block (connect to previous IO Blox), 8 inputs/8 outputs, cables included (0.3 m) | 90356-30100 | ||

| IO Blox-to-robot Cable, 3 m | 04677-030 | ||

| IO Blox-to-IO Blox Cable, 3 m | 04679-030 | ||

| IO Blox-to-IO Blox Cable, 0.3 m | 04679-003 | ||

| XIO Termination Block, 12 inputs/8 outputs, cables included (1.8 m) | 90356-40100 | ||

| XDIO Termination Block, 50 pin, cables included (2 m) | 09747-000 | ||

|

Front Panel | Front Panel with 3 m cable | 90356-10358 |

| Front Panel Cable, 3 m | 10356-10500 | ||

| Power Supply/Cable | AC Power Cable, 5 m | 04118-000 | |

| 24 VDC Power Cable, 5 m | 04120-000 | ||

| 24 VDC, 6.5 A, 150 W (Front Mounting), Power Supply | S8FS-G15024C

2

Refer to the Switch Mode Power Supply Datasheet

(Cat.No.T207) for details. |

||

| 24 VDC, 6.5 A, 150 W (DIN-Rail Mounting), Power Supply | S8FS-G15024CD

2

Refer to the Switch Mode Power Supply Datasheet

(Cat.No.T207) for details. |

||

| 1394 Cable, 4.5 m | 13632-045 | ||

| eAIB XSYSTEM Cable Assembly, 1.8 m | 13323-000 | ||

| DB9 Splitter, 0.3 m | 00411-000 | ||

| eAIB XSYS Cable, 4.5 m | 11585-000 | ||

| Ethernet Cable | XS6W-6LSZH8SS

2

Refer

to the Industrial Ethernet Cables Catalog (Cat.No.G019) for details. |

||

| Industrial Switching Hubs | W4S1-05C

2

Refer

to the Industrial Switching Hubs Catalog (Cat.No.V227) for details. |

||

| Solenoid Valve Kit | eCobra robots (600, 800, 800 Inverted) | 02853-000 | |

| Cable Seal Kit | Hornet 565 IP65/67, Quattro 650HS IP65/67, Quattro 800HS IP65/67 | 08765-000 | |

| Quattro 650HS Standard, Quattro 800HS Standard | 09564-000 | ||

| eCobra 800 IP65/67 | 04813-000 | ||

| eCobra 800 Inverted IP65 | 09073-000 | ||

|

ACE License | Automation Control Environment (for ACE 4.x) | Please download it from following URL: http://www.adept.com/Robots-Tool |

| ACE PackXpert (for ACE 4.x) | 20409-000 | ||

| ACE Sight Vision Software (for ACE 4.x) | 20410-000 | ||

| ACE PackXpert with ACE Sight Vision (for ACE 4.x) This license contains an ACE PackXpert license and an ACE Sight license. |

20433-000 | ||

|

Related Products | Machine Automation Controller NX/NY/NJ Series | NX/NY/NJ

2

Refer to the Sysmac Catalog (Cat.No.P072)

for details. |

| Automation Software Sysmac Studio | SYSMAC-SE2

2

Refer to the Sysmac Catalog (Cat.No.P072)

for details. |

||

| Collection of software functional componentsSysmac LibraryAdept Robot Control Library | SYSMAC-XR009

2

Refer

to the Sysmac Library Catalog (Cat.No.P106) for details. |

||

| Sysmac Studio 3D Simulation option | SYSMAC-SA4 |

||

Contact your Omron representative for lenses, lights, and licenses.

Sysmac Library

The Sysmac Library is a collection of software functional components that can be used in programs

for the NX/NY/NJ Machine Automation Controllers.Please download it from following URL and install to Sysmac Studio Automation Software.http://www.ia.omron.com/sysmac_library/The Adept Robot Control Library allows you to control Delta, Articulated and SCARA robots manufactured

by Omron Adept Technologies Inc. from the NX/NY/NJ Machine Automation Controller by using the same

instructions and programming methods.

Aveţi nevoie de asistenţă?

Suntem aici pentru a vă ajuta! Contactaţi-ne, iar specialiştii noştri vă vor ajuta să găsiţi cea mai bună soluţie pentru afacerea dvs.

Contactați-mă Hornet

Vă mulțumim pentru solicitarea trimisă. Vom reveni cu un răspuns cât mai curând posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadOfertă pentru Hornet

Prin completarea acestui formular puteţi face o cerere de ofertă. Vã rugãm completaţi toate câmpurile marcate cu *. Datele dumneavoastrã personale vor fi tratate cu confidențialitate.

Vă mulțumim pentru cererea de ofertă trimisă. Vă vom oferi informațiile cerute în cel mai scurt timp posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadSeria de Roboţi Delta

Hornet 565

- Domeniu de lucru nominal: Ø 1.130 x 275 mm (max. 425 mm)

- Sarcină utilă max.: de la 3 la 8 kg

- Număr de axe: 3 + 1 (axă de rotaţie opţională)

- IP65

Unităţi de comandă

Videoclipuri

-

Omron PackXpert: complete packaging solution

A complete single source integrated solution: robot, vision, motion, design & control. Manage your packaging line on your own with an intuitive, graphical interface. PackXpert Solution brings together our complete line of robotic automation products into a single, fully integrated packaging system. From design to implementation to product changeovers, with PackXpert, you’ll save time, lower costs and reduce the complexity of your packaging line.

01:21

_getting_started_guide_en.jpg)

_users_manual_en.jpg)