E5_D/H

Următoarea generație de controlere

E5_D/H reprezintă următoarea generație de controlere proiectate pentru a atinge și a controla automat temperatura optimă fără a fi nevoie de interacțiunea umană. De fapt, de acum înainte, toate modificările tipice realizate în acest domeniu de experți, sunt acum automatizate folosind inteligența artificială A.I.

- „Tehnologia de control adaptiv„ detectează automat modificările din procesul controlat și ajustează PID-ul corespunzător.

- Funcții specializate pentru utilaje de ambalare și extrudere răcite cu apă

- Afișaj LCD de mari dimensiuni, cu contrast ridicat, alb clar - vizibil de la distanțe mari și sub unghiuri ample de vizualizare

- Funcție de comutare între bancuri(grup PID), pentru schimbări rapide ale setărilor dispozitivului (doar pentru modelul E5_D-H).

- Funcția de pre-încălzire în 5 pași pentru a reduce fluctuațiile previzibile de temperatură (doar pentru modelul E5_D-H).

Specificaţii şi informaţii pentru comenzi

| Produs | Size | Functions | Number of control loops | Temperature input type | Linear analog input type | Temperature range | Features | Number of event inputs | Number of alarm outputs | Supply voltage AC | Supply voltage DC | Control output | Communication port(s) | Terminal type | Descriere | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Linear current output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Linear current output,, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Voltage pulse output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Voltage pulse output, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Relay output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Relay output, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 100-240 V | Voltage pulse | Serial RS-485 | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX, RS-485, Ht. Burnout SSR fail., 100 to 240 VAC |

|

||

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX,RS-485, Ht. Burnout SSR fail., 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX,RS-485, Ht. Burnout SSR fail., 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 24 VAC/DC |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 24 VAC/DC |

|

||

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Linear current outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | 2 Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Linear current outputs, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | Linear current, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Linear current output, Voltage pulse output, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | Linear current, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Linear current output, Voltage pulse output, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Voltage pulse outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | 2 Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Voltage pulse outputs, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | Relay, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Voltage pulse output, Relay output, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | Relay, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Voltage pulse output, Relay output, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Relay outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

Aveţi nevoie de asistenţă?

Suntem aici pentru a vă ajuta! Contactaţi-ne, iar specialiştii noştri vă vor ajuta să găsiţi cea mai bună soluţie pentru afacerea dvs.

Contactați-mă E5_D/H

Vă mulțumim pentru solicitarea trimisă. Vom reveni cu un răspuns cât mai curând posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadOfertă pentru E5_D/H

Prin completarea acestui formular puteţi face o cerere de ofertă. Vã rugãm completaţi toate câmpurile marcate cu *. Datele dumneavoastrã personale vor fi tratate cu confidențialitate.

Vă mulțumim pentru cererea de ofertă trimisă. Vă vom oferi informațiile cerute în cel mai scurt timp posibil.

Întâmpinăm dificultăţi tehnice. . Formularul dumneavoastră nu a fost preluat cu succes. Vă rugăm să acceptaţi scuzele noastre şi să încercaţi încă odată mai târziu. Detalii: [details]

DownloadCaracteristici

Adaptive control algorithm

-

E5_D Temperature contoller: Adaptive control algorithm

With standard temperature controllers, not only do you need a long time to define initial start-up PID settings, but it is also really challenging to make the optimal adjustments without having many years of experience in this area. That’s why Omron developed the E5_D Series with “adaptive control technology”. This automatically detects changes in the process under control and adapts the PID accordingly.

01:26

La controlerele de temperatură standard, definirea setărilor PID iniţiale de pornire este nu numai o operațiune consumatoare de timp, dar efectuarea reglajelor optime fără o experienţă îndelungată în domeniu se poate dovedi dificilă. De aceea Omron a creat seria E5_D cu tehnologie de control adaptivă. Aceasta detectează automat modificările din procesul controlat şi adaptează regulatorul PID în consecinţă. Rezultatul? Un algoritm PID perfect reglat şi un control foarte stabil al temperaturii.

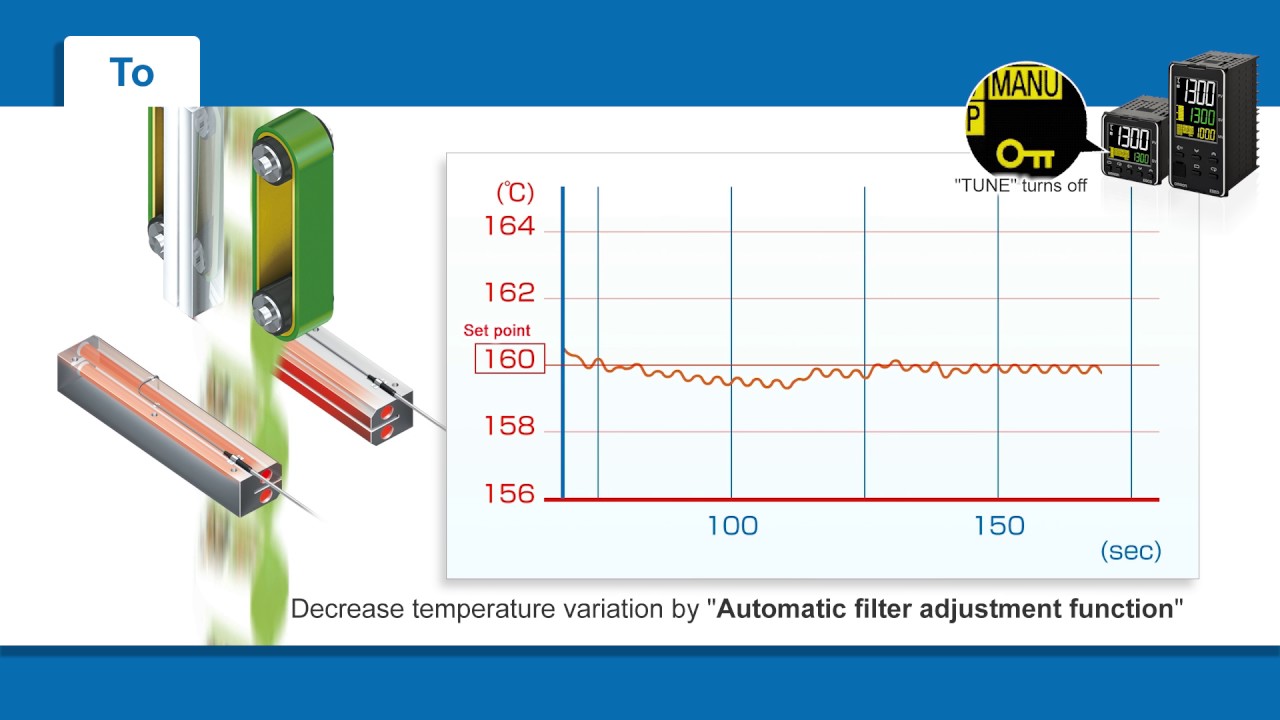

Perfect sealing temperature control for packaging machines

-

E5_D TC: Perfect sealing temperature control for packaging machines (1)

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:25

La utilajele de etanşeizare convenţionale, senzorii de temperatură sunt deseori situaţi prea departe de suprafaţa de etanşare a barei de încălzire. Aceasta creează o diferenţă între temperatura suprafeţei de etanşare şi temperatura efectiv controlată. Această diferenţă de temperatură şi erorile de etanşare rezultate se măresc o dată cu viteza de ambalare şi, de asemenea, în corelaţie cu materialele de ambalare mai subţiri sau cu temperatura ambientală.

Datorită seriei E5_D, această problemă este rezolvată prin următoarea metodă:

- apropierea senzorului de suprafaţa de etanşare - datorită modelelor speciale de senzori de temperatură, pentru o detecţie mai rapidă

-

E5_D: Perfect sealing temperature control for packaging machines (2)

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:03

- adoptarea unor algoritmi speciali (funcţie de reglare automată a filtrării) integraţi în seria E5_D, special realizaţi pentru suprimarea variaţiilor de temperatură. Rezultatul este o mai bună calitate a etanşării ambalajelor.

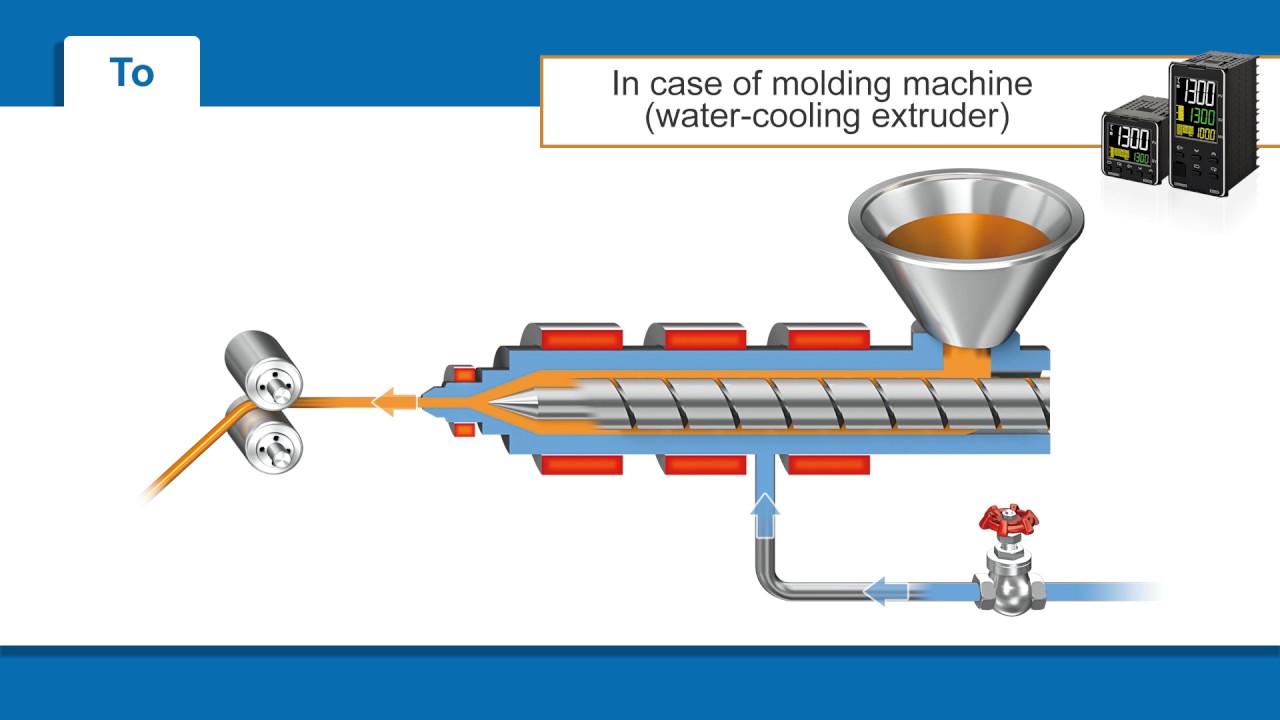

Water cooling output adjustment

-

E5_D TC: Temperature variations in molding machines minimized by a new algorithm

On a water-cooled extrusion molding machine, increased speed leads to temperature variations due to various factors such as the materials compounding and cooling water…For human operator that means repeatedly make valve adjustments to stabilize the quality. However It is really difficult to achieve high speed production while also maintaining the quality… With the E5_D, the water-cooling output adjustment function suppresses the temperature variations to a minimum and raises the production capacity with the quality maintained

01:33

La utilajele de extrudare răcite cu apă, viteza mărită conduce la variaţii de temperatură datorită diferiţilor factori cum ar fi materialele utilizate şi apa de răcire… Pentru operatorul uman acest lucru înseamnă repetarea unor modificări la nivelul valvelor pentru stabilizarea calităţii. Cu toate acestea, este foarte dificil să se realizeze o producţie la o viteză ridicată şi să se menţină calitatea în acelaşi timp...

Pentru seria E5_D, funcţia de ajustare a ieșirii în corelare cu apa de răcire reduce variaţiile de temperatură la minim şi crește capacitatea de producţie, menţinând calitatea.

Documentare

_cg_en.jpg)

Vă rugăm să vă conectaţi sau înregistrare la conţinutul de pe această pagină.

_cg_en.jpg)

Vă rugăm să vă conectaţi sau înregistrare la conţinutul de pe această pagină.